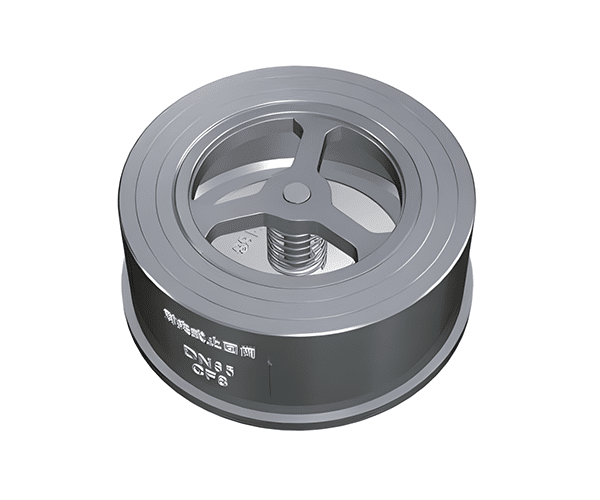

spring loaded wafer check valve

spring loaded wafer check valve

spring loaded wafer check valve

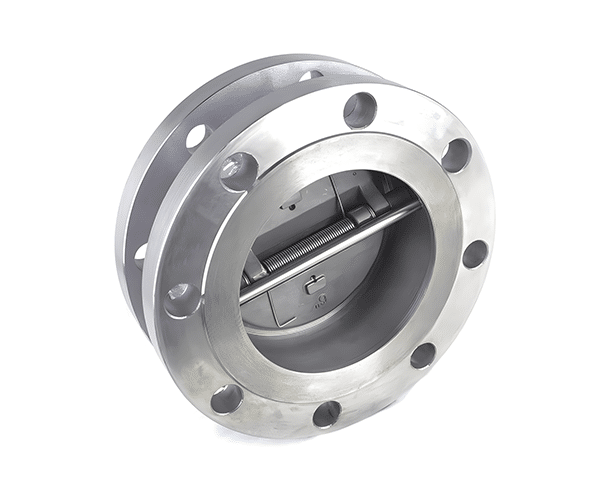

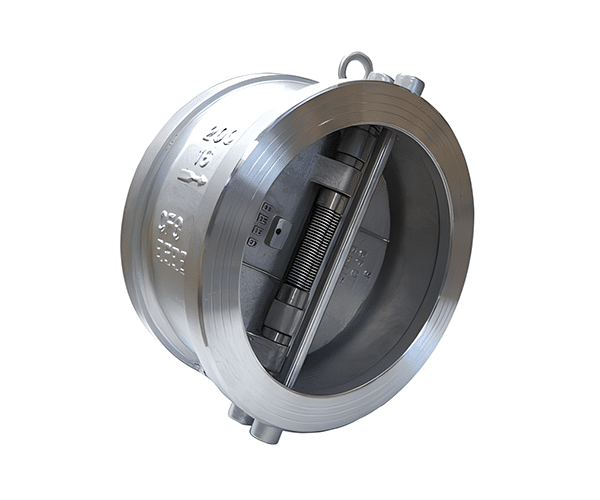

Product Overview | The Spring Loaded Wafer Check Valve is a compact, high-performance non-return valve designed to prevent reverse flow in piping systems requiring rapid closure and minimal pressure drop. Featuring a spring-assisted disc and wafer-style design, this valve ensures immediate sealing upon flow reversal, making it ideal for applications where water hammer prevention and space efficiency are critical. Constructed from stainless steel, carbon steel, or ductile iron, this valve is durable and corrosion-resistant, suitable for water, steam, oil, and gas systems. Its lightweight, flangeless design simplifies installation and reduces system weight, while the spring mechanism enhances reliability in dynamic flow conditions. |

Key Features | Spring-Assisted Closure:Integrated spring ensures rapid disc closure, minimizing water hammer and backflow risks.Low cracking pressure (as low as 0.1 psi) for efficient operation. Wafer Design:Compact and lightweight, ideal for space-constrained installations.Installed between flanges without additional bolts or gaskets. Low Resistance Design:Optimized flow path minimizes pressure drop, reducing energy consumption.Suitable for high-flow systems such as HVAC and water distribution networks. Durable Construction:Body materials: Stainless steel (ASTM A351 CF8M), Carbon steel (ASTM A216 WCB), or Ductile iron (EN-GJS-400-18).Internals: Stainless steel disc and spring for corrosion resistance. Compliance:Meets API 594, ASME B16.34, and ISO 17292 standards for industrial applications. |

Operational Advantages | Rapid Closure: Spring mechanism ensures instant sealing, preventing backflow and water hammer. Energy Efficiency: Low pressure drop reduces pump workload and energy costs. Space-Saving: Wafer design minimizes installation space and system weight. Low Maintenance: Self-cleaning disc and corrosion-resistant materials extend service life. |

Why Choose Our Spring Loaded Wafer Check Valve? | Proven Reliability: Trusted in HVAC, water treatment, and industrial systems. Global Compliance: Meets API, ASME, and ISO standards for international projects. Custom Solutions: Optional coatings (epoxy, PTFE) or high-temp materials (Inconel). Fast Delivery: Standard sizes in stock with 7-day global shipping. |

Product Parameters

| Size Range | 2" to 24" (DN50 to DN600) |

| Pressure Rating | Class 150 to Class 900 (ASME B16.34) |

| Temperature Range | -29°C to 200°C (-20°F to 392°F) |

| Body Materials | Stainless Steel (CF8M), Carbon Steel (WCB), Ductile Iron (EN-GJS-400-18) |

| Disc Material | Stainless Steel (316/304) |

| Spring Material | Stainless Steel (Inconel X750 for high-temp applications) |

| End Connections | Wafer (fits between ANSI/EN/DIN flanges) |

Working conditions

Summarize

spring loaded wafer check valve Related Products

The following are similar products. You can search for other related products.