The company was founded in 2014 and is an all-around manufacturer that specializes in the design, research and development, mechanical processing, assembly, performance testing, and testing of liquid control, electric, pneumatic, butterfly valves, and ball valves. The manufacturer is located in Oubei Town, Wenzhou, known as the hometown of pumps and valves in China, with superior geographical location and transportation conditions. The manufacturer covers a total area of 5000 square meters and currently has more than 70 employees; There are 16 engineering and technical personnel….

We have strict production process and factory inspection equipment and processing equipment.

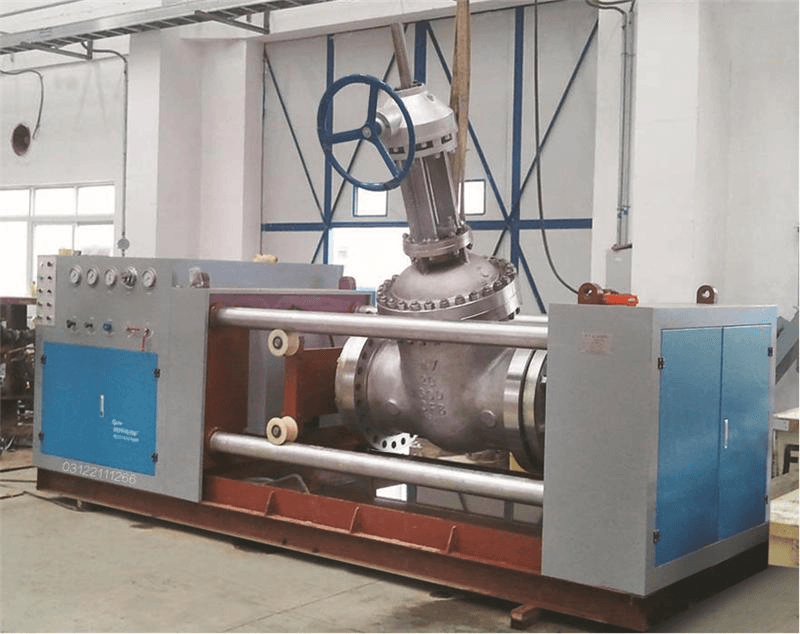

Valve testing equipment

We are more concerned about product quality than you are. We have complete testing equipment, including blank testing, material composition testing, process testing and factory testing. Every valve must be tested before leaving the factory.

Automated processing equipment

We use advanced automated processing equipment, including high-precision robotic arms and automatic welding machines, to achieve full process automation from raw material processing to finished product assembly. This significantly improves production efficiency and reduces labor costs. By integrating these devices, we not only improve product quality, but also enhance the flexibility and response speed of the production line to meet the diverse needs of customers.

Mass production

We focus on mass production and realize the automation of the whole process of valve production. The mass production mode not only greatly improves production efficiency, but also ensures the consistency and stability of product quality. The efficient operation of automated equipment reduces manual intervention, reduces production costs, and speeds up delivery.

The following are common questions. Please contact us for more questions.

We provide a wide range of valve products, including but not limited to ball valves, butterfly valves, gate valves, stop valves, check valves, diaphragm valves, etc. Our valves are suitable for many industries such as petroleum, chemical, electric power, food, pharmaceutical, metallurgy, etc., and valves with special specifications and functions can be customized according to customer needs.

Yes, all our products are manufactured in strict accordance with international standards such as API, ASME, ISO, GB, etc. and have passed relevant quality certifications. We are committed to providing customers with high-quality and reliable products.

Yes, we offer custom services and can design and manufacture valves to meet your specific needs. Whether it is special size, material selection or functional requirements, we can meet it. Please contact our sales representative for more information.

The delivery time depends on the specific content and quantity of the order. For standard products, it can usually be shipped within 1-2 weeks; for customized products, the delivery time may be slightly longer, depending on the complexity of the project. We will try our best to shorten the delivery cycle and keep you informed of the latest progress.

We keep a limited number of commonly used valve models in stock to quickly respond to customer needs. For products that are in urgent need, we can ship them immediately. If you need to check the stock status of a specific model, please contact our customer service team.

We take a number of measures to ensure product quality:

Strict quality management system: We follow the ISO9001 quality management system and conduct strict quality control at every stage from raw material procurement to finished product delivery.

Advanced testing equipment: Equipped with high-precision testing instruments such as three-coordinate measuring machines and spectrometers to ensure that every component meets the design requirements.

Professional talent team: We have an experienced and skilled quality inspection team, and receive regular training to ensure that we can accurately judge product quality.

Full process monitoring: From the entry of raw materials into the factory to the delivery of the final product, we implement full process tracking management to ensure that every step is carried out under controlled conditions.

Customer feedback mechanism: We have established a complete customer feedback mechanism to collect and process customer opinions and suggestions in a timely manner and continuously improve product quality.

No, our company only produces some commonly used valves, and we provide the other valves through our other supply chains in China. Because there are too many types of valves, if we produce all of them, the cost will be very high and the production cycle will be long. We will strictly control our suppliers just like we treat our own products.

We have gained a good reputation in the market with our strong product strength and good service.

We look forward to seeing you

If you are interested in our products, or our products are what you need, you can contact us.

We’ve been waiting