axial nozzle check valve

axial nozzle check valve

axial nozzle check valve

Product Overview: | The Axial Nozzle Check Valve is designed to prevent backflow in high-pressure pipelines, ensuring that fluid or gas only flows in one direction. It is commonly used in industries such as oil and gas, power generation, petrochemical, and water treatment, where controlling fluid direction is crucial for system protection and efficiency. The valve features a streamlined design that minimizes flow resistance, reducing energy consumption and increasing operational efficiency. |

Product Features: | Axial Flow Design: The valve is engineered with an axial flow design, meaning that the flow path of the medium is in line with the valve's body, reducing turbulence and pressure drop. This allows for smoother operation, particularly in high-pressure applications. No Slam Operation: Equipped with a no-slam feature, the valve ensures smooth, quick, and controlled closure. This prevents damage to the valve and pipeline by avoiding the "slamming" effect that occurs in traditional check valves, especially in high-velocity fluid applications. Precision Nozzle: The nozzle design ensures precise control of the fluid flow, improving sealing efficiency and minimizing the chances of valve leakage. The nozzle also helps in reducing erosion and wear on valve components. Hard Seal Materials: Given its application in high-pressure systems, the axial nozzle check valve uses durable, hard sealing materials to withstand extreme pressure and temperature conditions. The hard seal ensures longer service life and reliable performance even under the most demanding conditions. Compact and Robust Construction: With its compact and robust design, the valve is well-suited for installation in confined spaces, particularly in critical pipeline systems where space is limited, and operational reliability is paramount. |

Advantages: | High Pressure Resistance: The axial nozzle check valve is ideal for use in systems with pressures ranging from medium to ultra-high pressures (up to 2500 LB or higher), ensuring safety and longevity in demanding applications. Minimized Flow Resistance: Thanks to the axial flow design, this valve minimizes energy loss due to flow resistance, which can be particularly beneficial in systems where energy efficiency is a key concern. Reliable Backflow Prevention: The valve is designed to provide reliable backflow prevention without requiring external power sources, offering a failsafe method to control fluid movement in pipelines. Durability and Reliability: The valve’s components are crafted from high-quality materials, such as stainless steel or alloy steel, ensuring that it can handle extreme operating conditions while maintaining optimal performance. Easy Maintenance: The valve design allows for easy maintenance and service, with accessible parts and simple functionality that reduces downtime and operating costs.

|

Difference Between Axial Nozzle Check Valve and Ordinary Axial Flow Check Valve | 1. Fluid Flow Path Design: Ordinary Axial Flow Check Valve: In contrast, the ordinary axial flow check valve has a relatively simple 2. Flow Control and Pressure Loss: Ordinary Axial Flow Check Valve: Ordinary axial flow check valves have a simpler structure, which may result in higher flow resistance and greater pressure loss. This can lead to increased energy consumption and reduced system 3. Sealing Performance: Ordinary Axial Flow Check Valve: Ordinary axial flow check valves rely more on valve disk and spring components for sealing. While they can achieve basic flow prevention, they may not perform as well in applications requiring high sealing accuracy under extreme pressures or temperatures. |

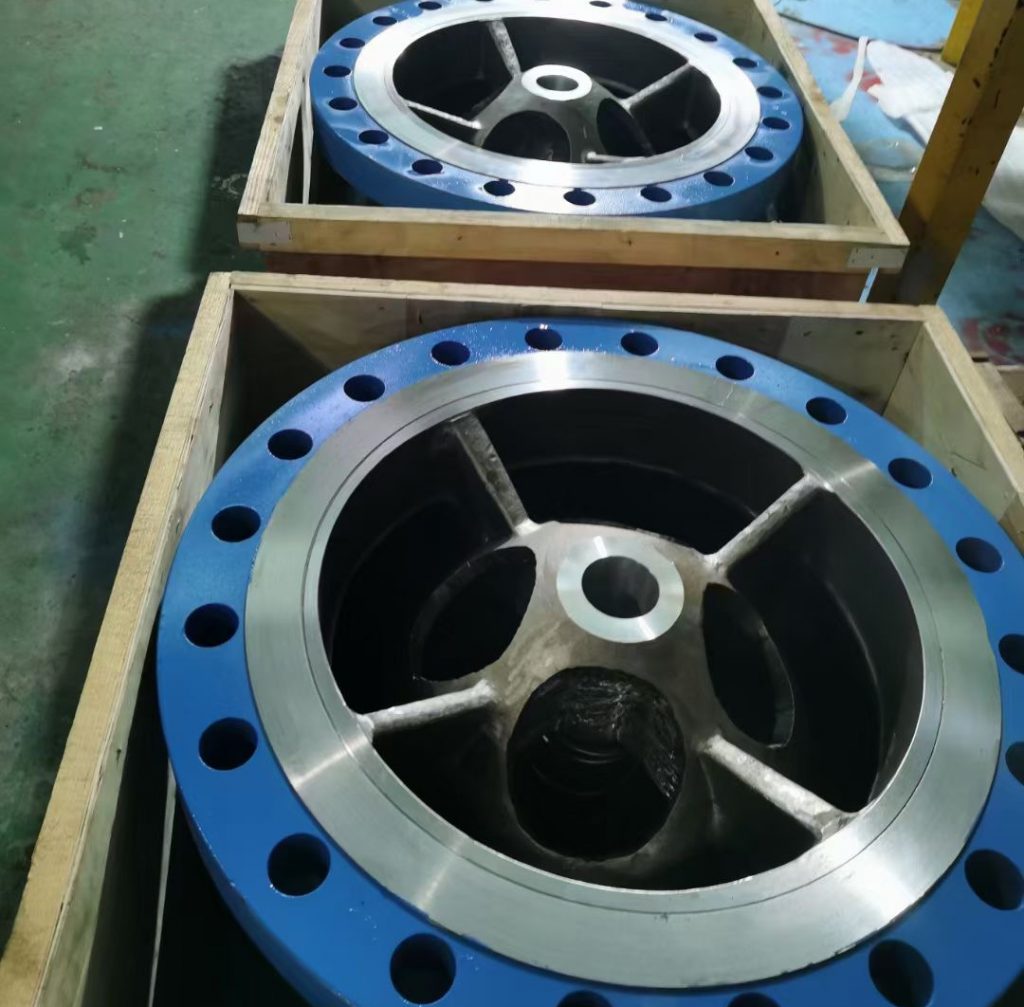

Product Photos |

|

Product Parameters

| Nominal Diameter | 2-48 inch;DN50-DN1200 |

| Nominal Pressure | PN6-PN64,150LB-600LB |

| Temperature Range | -20°C to 450°C |

| Body Material | Carbon Steel, Stainless Steel |

| Seal Material | Hard Seals (Metal to Metal) |

| Connection | Flanged, Butt-Welded |

| Flow Direction | Unidirectional |

| Nozzle Material | Alloy Steel, Stainless Steel |

Working conditions

Summarize

axial nozzle check valve Related Products

The following are similar products. You can search for other related products.