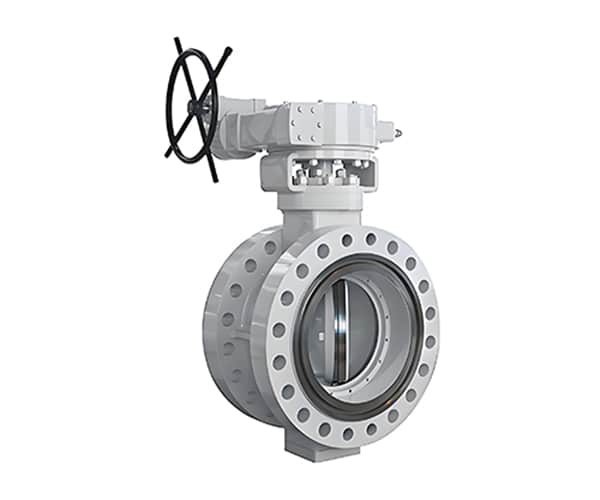

Metal to Metal Hard Seal Butterfly Valve

Metal to Metal Hard Seal Butterfly Valve

Metal to Metal Hard Seal Butterfly Valve

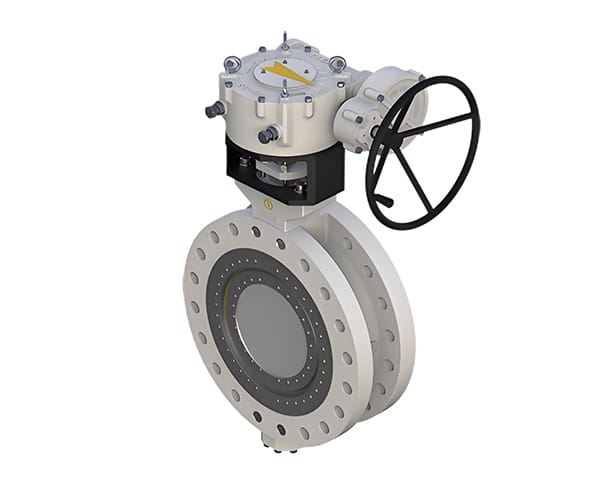

Product Description | The metal-to-metal hard seal butterfly valve is a high-performance industrial valve designed for demanding conditions. Its sealing surfaces are made entirely of high-hardness metal materials such as stainless steel or Stellite alloys, ensuring exceptional wear and corrosion resistance. This valve is specifically engineered for high-temperature, high-pressure, and harsh working environments, making it a preferred choice in industries like petrochemical, power generation, metallurgy, and thermal systems requiring reliable sealing. The metal sealing surfaces undergo precise machining and specialized surface treatments (e.g., hard alloy overlay or nickel plating), delivering excellent sealing performance and extended service life, even in extreme operating conditions. |

Product Features | Metal-to-Metal Sealing Structure:Pure metal sealing pairs eliminate the need for non-metallic materials, ensuring superior resistance to high temperatures, abrasion, and corrosion.The high-hardness sealing surfaces resist erosion from solid particles and impact from high-pressure fluids. High Temperature and High-Pressure Suitability:Operating temperature range: -60°C to 600°C (depending on material selection).Pressure rating: Supports high-pressure applications, commonly PN25 to PN40 and above. Bi-Directional Sealing:Offers reliable sealing in both flow directions, simplifying system design and installation. Extended Service Life:Durable sealing surfaces minimize maintenance and reduce costs associated with frequent part replacement. Wide Application Range:Suitable for various media, including high-temperature steam, molten salts, corrosive gases, and liquids containing solid particles. |

Difference Between Metal-to-Metal Hard Seal Butterfly Valves and Multi-Layer Hard Seal Butterfly Valves | Sealing Structure: Metal-to-Metal Hard Seal Butterfly Valve: Fully metallic sealing pairs provide superior resistance to extreme conditions. Temperature and Pressure Range: Metal-to-Metal: Wider temperature and pressure range, suitable for extreme environments. Durability and Maintenance: Metal-to-Metal: Longer lifespan with less frequent maintenance. Application Scenarios: Metal-to-Metal: Ideal for extreme environments with high temperatures, pressures, or corrosive media. |

Advantages | Exceptional Performance in Extreme Conditions:Reliable sealing under high temperature, high pressure, and corrosive environments. Longevity:Precision machining and durable materials ensure extended valve life. Bi-Directional Sealing Capability:Provides flexibility and convenience for system design and installation. Low Maintenance Costs:Reduces downtime and expenses related to frequent part replacements. |

Product Parameters

| Nominal Diameter | 2 -64 inch ,( DN50-DN1600 ) |

| Nominal Pressure | PN10-PN40 ( 150LB-300LB ) |

| Temperature Range | -60°C to +600°C (depending on material selection) |

| Connection Type | Wafer, Lug, Double Flange, or Butt Weld |

| Seal Type | Metal-to-Metal (Stainless Steel or Stellite overlay) |

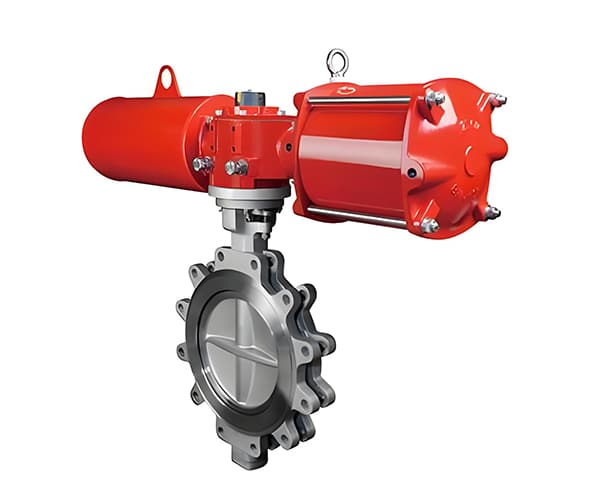

| Actuation | Manual, Electric, Pneumatic, or Hydraulic |

| Body Material | WCB (carbon steel), CF8/CF8M (304/316 stainless steel), C95800 (nickel-aluminum bronze), or other custom alloys |

| Disc Material | WCB (carbon steel), CF8/CF8M (304/316 stainless steel), C95800 (nickel-aluminum bronze), or other custom alloys |

| Seat Material | Stainless steel, Stellite, or other hard alloys |

Working conditions

Summarize

Metal to Metal Hard Seal Butterfly Valve Related Products

The following are similar products. You can search for other related products.