butt weld metal seated butterfly valve

butt weld metal seated butterfly valve

butt weld metal seated butterfly valve

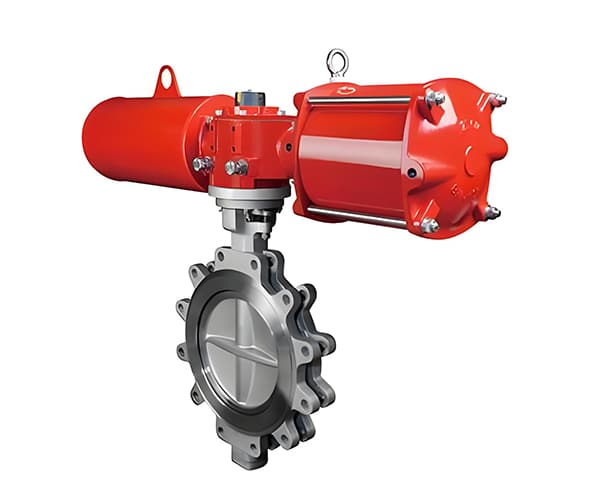

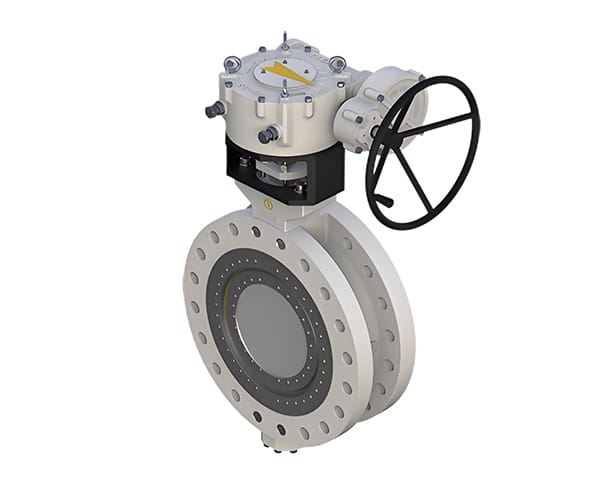

Product Overview | The Butt Weld Metal Seated Butterfly Valve is engineered to provide superior performance in demanding industrial applications. Its butt-weld connection delivers a leak-proof and secure integration into pipelines, while the metal-seated design ensures durability in high-pressure and high-temperature environments. This valve is widely used in applications requiring exceptional reliability, such as petrochemical plants, power generation facilities, and metallurgical processes.

|

Key Features | Butt-Weld Connection:Provides a strong, permanent joint, minimizing the risk of leakage. Metal Seated Design:Precision-engineered metal-to-metal sealing for enhanced durability. Triple Offset Structure:Eliminates contact between the disc and seat during operation, reducing wear and prolonging valve life. Robust Material Selection:Available in carbon steel, stainless steel, duplex steel, and alloy steel for mechanical strength and corrosion resistance. Optimized Temperature Range:Designed to operate reliably within -60°C to 450°C, accommodating a wide range of industrial conditions. Flexible Actuation Options:Supports manual, pneumatic, electric, or hydraulic actuators to meet diverse control requirements. |

Advantages | High Temperature and Pressure Resistance:Ideal for medium-to-high-pressure systems and temperatures up to 450°C, ensuring reliable performance in demanding conditions. Enhanced Durability:Metal sealing offers superior resistance to wear and corrosion, even in aggressive media. Secure and Leak-Proof Design:Butt-weld connection eliminates potential leak paths, enhancing safety and system efficiency. Wide Media Compatibility:Suitable for handling steam, gases, oils, and corrosive chemicals. Low Maintenance Requirements:Triple offset design minimizes wear, reducing maintenance costs and extending service life. |

Product Parameters

| Nominal Diameter | 2-48 inch;DN50-DN1200 |

| Nominal Pressure | PN10-PN40 (150LB-300LB ) |

| Body Material | Carbon Steel, Stainless Steel, Duplex Steel, Alloy Steel |

| Body Material | Carbon Steel, Stainless Steel, Duplex Steel, Alloy Steel |

| Disc Material | Carbon Steel, Stainless Steel, Duplex Steel, Alloy Steel |

| Seal Material | Metal Seat (Stainless Steel, Alloy Steel) |

| Temperature Range | -60°C to 450°C |

| Connection Type | Butt Weld |

| Leakage Rate | Class V or VI |

| Actuation Options | Manual, Pneumatic, Electric, Hydraulic |

| Standards Compliance | API 609, ISO 5752, EN 593, ASME B16.34 |

Medium

Working conditions

Summarize

butt weld metal seated butterfly valve Related Products

The following are similar products. You can search for other related products.