electric hard seal butterfly valve

electric hard seal butterfly valve

electric hard seal butterfly valve

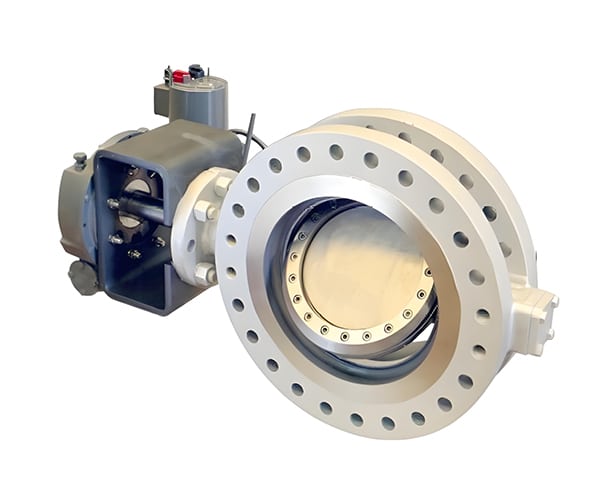

Product Overview: | The Electric Hard Seal Butterfly Valve is an advanced, highly durable valve designed for precise and reliable flow control in industries requiring exceptional sealing performance under extreme conditions. This valve features an integrated electric actuator for fully automated operation, enabling centralized control, enhanced safety, and ease of remote management. The hard seal technology, typically comprising metal-to-metal sealing, ensures tight shutoff even under high pressure and high-temperature conditions. The valve is primarily used in industries like petrochemical, power generation, chemical processing, and HVAC, where reliable isolation and regulation are critical. |

Key Features: | Electric Actuation: Equipped with an electric actuator, the valve allows for automated operation, facilitating remote control and integration into larger automated control systems. Hard Seal Structure: The valve is equipped with a hard-seal design that provides a strong, leak-tight closure. The sealing surfaces typically consist of metal-to-metal materials, ensuring long-term durability even under extreme temperatures and pressures. Durability in Extreme Conditions: Capable of withstanding temperatures up to 450°C and pressures up to PN40, the electric hard seal butterfly valve is suitable for handling steam, high-temperature gases, and aggressive fluids. Compact and Efficient Design: Known for its lightweight and compact design, the butterfly valve allows for easier installation and operation in space-constrained environments. The low operational torque also ensures smooth and energy-efficient functioning. Fail-Safe Mechanism: Optional spring return actuators ensure the valve can fail to the safe position (open or closed) in case of power loss, further increasing system reliability. Wide Material Options: Available in high-strength materials like carbon steel, stainless steel, and alloy steel, this valve is well-suited to high-performance applications requiring corrosion resistance, toughness, and resistance to wear. Versatile Sealing: The hard seal design makes it ideal for applications involving high pressure, extreme temperatures, and abrasive media. |

Advantages | Reliable Sealing: The hard seal ensures zero leakage even in high-temperature and high-pressure conditions, making it highly suitable for critical applications where leak-tight shutoff is essential. Energy Efficiency: The electric actuator is more energy-efficient compared to pneumatic alternatives, and the valve's low torque requirements minimize energy consumption during operation. Reduced Maintenance: With its robust design and durable sealing materials, the valve offers a longer service life, which reduces maintenance and replacement costs. Automation and Control: The integration of electric actuators allows for seamless automation and remote operation, making the valve ideal for modern process control systems that require remote monitoring and management. Versatility: The valve is highly versatile and can be used across multiple industries, including chemical processing, power plants, oil & gas, and HVAC, thanks to its capacity to handle a wide range of media and working conditions. |

Product Parameters

| Nominal diameter | DN50 - DN1600 (2”-64) |

| Nominal pressure | PN10-PN40 (150LB-300LB) |

| Body Material | Carbon Steel, Stainless Steel, Alloy Steel |

| Seat Material | Stainless Steel, Hard Seal Materials |

| Disc Material | Stainless Steel, Alloy Steel |

| Actuation Type | Electric Actuator |

| Sealing Type | Hard Seal (Metal-to-Metal) |

| Connections | Flanged, Wafer, Butt Welded |

| Actuator Voltage | 220V;380V;400V |

| Control Signals | ON/OFF, Modulating |

Working conditions

Summarize

electric hard seal butterfly valve Related Products

The following are similar products. You can search for other related products.