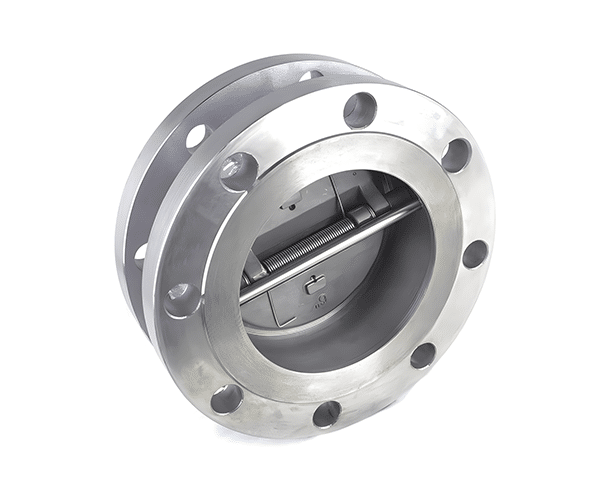

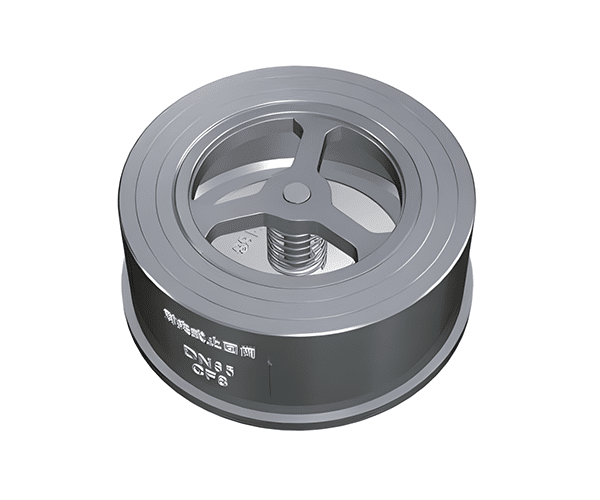

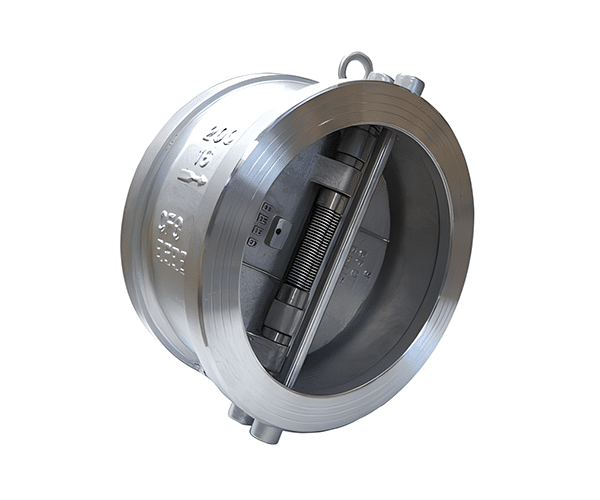

stainless steel wafer check valve

stainless steel wafer check valve

stainless steel wafer check valve

Product Overview | The Stainless Steel Wafer Check Valve is a corrosion-resistant, non-return valve designed to prevent reverse flow in demanding environments such as chemical processing, marine applications, and high-purity systems. Featuring a wafer-style design, this valve is installed between flanges, offering a compact, lightweight solution with minimal pressure drop. Constructed entirely from stainless steel (ASTM A351 CF8M/CF3M), this valve excels in handling corrosive media, high temperatures, and high-pressure conditions. Its swing disc or dual disc design ensures rapid sealing upon flow reversal, making it ideal for applications requiring reliability and durability. |

Key Features | Full Stainless Steel Construction:Body, disc, and fasteners made of CF8M (316 stainless steel) or CF3M (316L stainless steel).Resists pitting, crevice corrosion, and oxidation in aggressive media (e.g., chlorides, acids). Wafer Design:Compact and lightweight, ideal for space-constrained installations.Installed between ANSI/DIN/JIS flanges without additional bolts or gaskets. Low Resistance & Rapid Closure:Optimized flow path minimizes pressure drop.Swing disc or spring-assisted dual disc ensures immediate sealing to prevent water hammer. High-Temperature Capability:Operates reliably in temperatures up to 400°F (204°C), with optional materials for higher temperatures. Compliance:Meets API 594, ASME B16.34, ISO 17292, and NACE MR0175 standards. |

Operational Advantages | Corrosion Resistance: Ideal for harsh environments, including marine and chemical exposure. Hygienic Design: Electropolished surfaces (Ra ≤ 0.8 μm) meet FDA and EHEDG standards for sanitary applications. Low Maintenance: Self-cleaning design reduces fouling and extends service life. Versatility: Suitable for both high-purity and industrial corrosive media. |

Why Choose Us | Material Integrity: Full stainless steel construction ensures longevity in aggressive environments. Fast Delivery: Standard DN50-DN300 sizes in stock with global logistics support. Customization: Optional coatings (PTFE, DLC), high-temp springs, or specialty seals. Certifications: 3.1 Material Certificates, NACE compliance for sour service. |

Product Parameters

| Size Range | 2" to 24" (DN50 to DN600) |

| Pressure Rating | Class 150 to Class 900 (ASME B16.34) |

| Temperature Range | -29°C to 204°C (-20°F to 400°F) |

| Body Material | Stainless Steel (304/316/CF8M/CF3M) |

| Disc Material | Stainless Steel (316/316L) |

| Seat Material | EPDM, FKM, or PTFE (optional for chemical resistance) |

| End Connections | Wafer (fits ANSI 150/300/600, DIN, or JIS flanges) |

Medium

Working conditions

Summarize

stainless steel wafer check valve Related Products

The following are similar products. You can search for other related products.