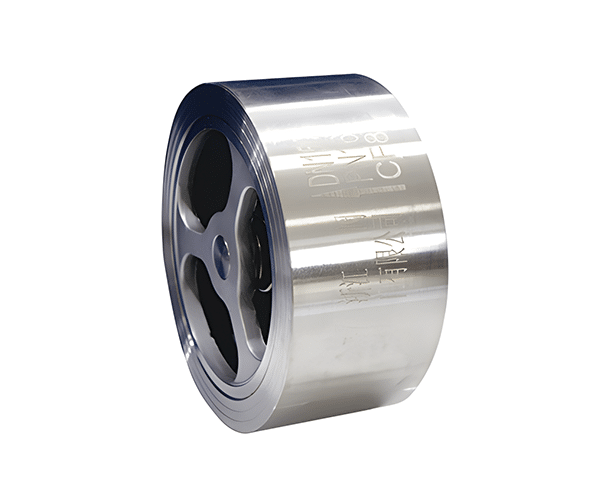

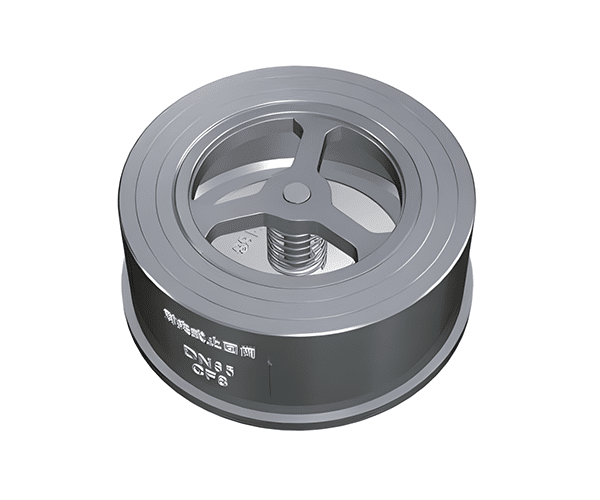

Silent clamp check valve

Silent clamp check valve

Silent clamp check valve

Product Overview | The Silent Clamp Check Valve is a hygienic, low-noise non-return valve designed for applications requiring quiet operation and easy maintenance, such as food & beverage, pharmaceutical, and bioprocessing industries. Featuring a silent closure mechanism and tri-clamp connections, this valve minimizes water hammer noise while ensuring rapid sealing to prevent backflow. Constructed from 316L stainless steel with electropolished surfaces (Ra ≤ 0.5 μm), this valve meets strict sanitary standards and resists corrosion in CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems. Its compact design and clamp connections allow for quick installation and disinfection, making it ideal for high-purity fluid handling. | |||||||||||||||

Key Features | Silent Closure Mechanism: Spring-assisted disc with a hydraulic damper ensures smooth, noise-free closure, reducing water hammer by up to 70%.Noise levels below 50 dB(A) during operation (compared to 80 dB(A) for standard check valves). Sanitary Clamp Connections: Tri-clamp (Tri-Clover) ends compliant with 3A, EHEDG, and FDA standards for hygienic applications.Easy disassembly for cleaning and inspection without tools. Hygienic Design: Full 316L stainless steel construction with electropolished or mirror-finished surfaces.No dead zones or crevices to prevent bacterial growth. Low Resistance Flow: Optimized flow path with minimal pressure drop (Cv ≥ 1.5 for DN50).Ideal for high-purity liquids such as dairy, beverages, and pharmaceuticals. Compliance: Meets 3A Sanitary Standards, EHEDG, ASME BPE, and ISO 2852. | |||||||||||||||

Operational Advantages | Noise Reduction: Engineered to operate below 50 dB(A), ideal for noise-sensitive environments. Easy Cleaning: Clamp connections and smooth surfaces simplify CIP/SIP processes. Zero Contamination: Hygienic design prevents product retention and microbial growth. Quick Installation: Tri-clamp ends enable fast assembly without welding or threading.

| |||||||||||||||

Comparison with Standard Check Valves |

| |||||||||||||||

Product Parameters

| Size Range | DN15 to DN300 (½" to 12") |

| Pressure Rating | 6bar-16 bar,150LB |

| Temperature Range | -10°C to 150°C (14°F to 302°F) |

| Body Material | 316L Stainless Steel (1.4404),WCB,A105 |

| Disc Material | 316L Stainless Steel with EPDM/FKM seals |

Working conditions

Summarize

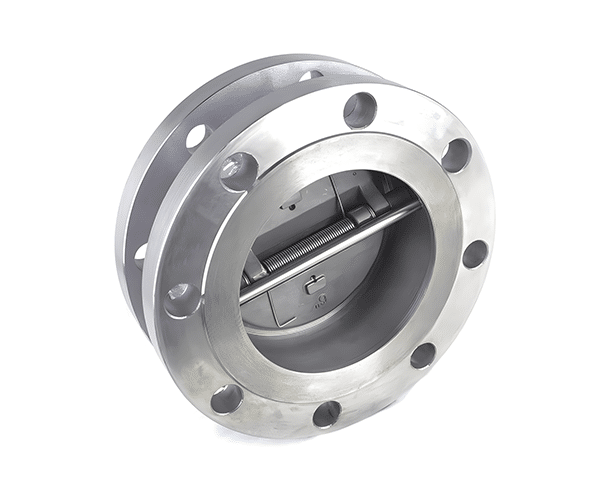

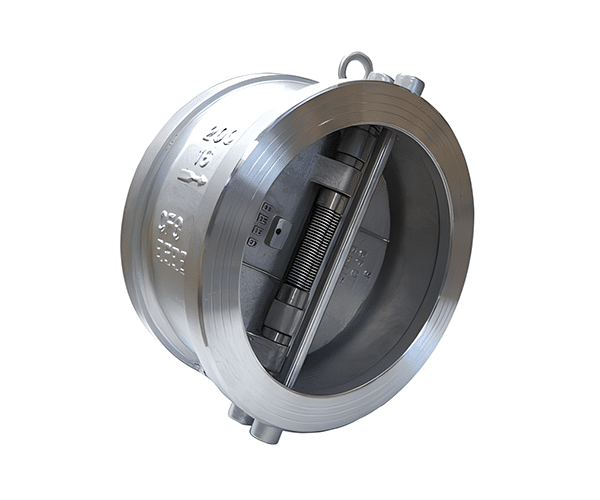

Silent clamp check valve Related Products

The following are similar products. You can search for other related products.