Low resistance backflow preventer

Low resistance backflow preventer

Low resistance backflow preventer

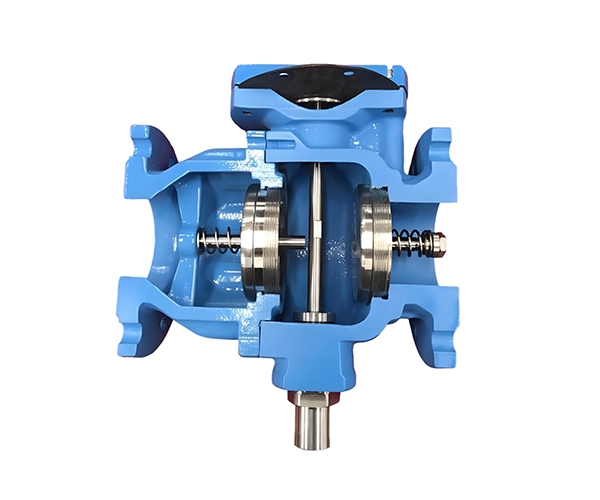

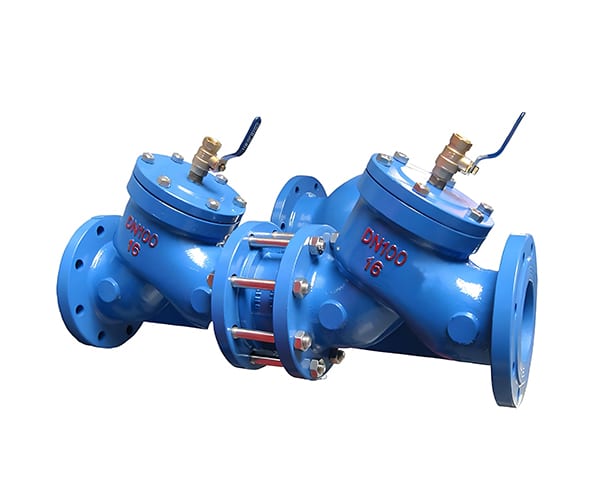

Product Overview | The Low Resistance Backflow Preventer is a high-efficiency device designed to prevent reverse flow and protect water supply systems from contamination while minimizing pressure drop. Featuring an optimized flow path and advanced sealing technology, this backflow preventer ensures reliable operation and energy efficiency in potable water, fire protection, and industrial systems. Constructed from stainless steel, bronze, or ductile iron, this valve is durable and corrosion-resistant, suitable for applications requiring high flow rates and low maintenance. Its low resistance design reduces energy consumption, making it an ideal choice for systems where pressure loss is a critical concern. | |||||||||||||||

Applications | Potable Water Systems: Protects municipal water supply networks from backflow contamination. Fire Protection: Installed in sprinkler systems and fire hydrant networks. Industrial Processes: Safeguards process water systems in chemical, pharmaceutical, and food industries. Irrigation: Prevents fertilizers and chemicals from entering the water supply.

| |||||||||||||||

Product Features | Low Resistance Design: Optimized flow path ensures minimal pressure drop (flow coefficient: Cv ≥ 1.5 for DN50).Ideal for high-flow systems such as water supply and fire protection networks. Reliable Backflow Prevention: Dual check valves with intermediate pressure relief chamber ensure zero backflow.Compliant with ASSE 1013, CSA B64.4, and EN 1717 standards. Durable Construction: Body materials: Stainless steel (316L), Bronze (C83600), or Ductile iron (EN-GJS-400-18).Internals: Stainless steel components for corrosion resistance and long service life. Low Maintenance: Self-cleaning design and easy-access inspection ports simplify maintenance.Replaceable seals and springs reduce downtime and repair costs. Compliance: Meets international standards such as ASSE 1013, CSA B64.4, and EN 1717. | |||||||||||||||

Operational Advantages | Energy Efficiency: Low resistance flow minimizes pump energy consumption. Water Safety: Dual check valves and pressure relief chamber ensure zero backflow contamination. Space Efficiency: Compact design reduces installation space and simplifies piping layouts. Ease of Maintenance: Self-cleaning design and replaceable components reduce downtime.

| |||||||||||||||

Comparison with Standard Backflow Preventers |

| |||||||||||||||

Product Parameters

| Size Range | DN50 to DN300 ( 2" to 12") |

| Pressure Rating | PN16 to PN25 (EN 1092) or Class 150 to Class 300 (ASME B16.34) |

| Temperature Range | -10°C to 120°C (EPDM seals) / -20°C to 80°C (NBR seals) |

| Body Materials | Stainless Steel (316L), Bronze (C83600), Ductile Iron (EN-GJS-400-18) |

| Seat Material | EPDM, NBR, or PTFE for zero leakage |

| End Connections | Flanged (EN 1092, ASME B16.5) |

| Leakage Class | Class VI (ISO 5208) |

Working conditions

Summarize

Low resistance backflow preventer Related Products

The following are similar products. You can search for other related products.