Hydraulically Controlled Slow Closing Check Valve

Hydraulically Controlled Slow Closing Check Valve

Hydraulically Controlled Slow Closing Check Valve

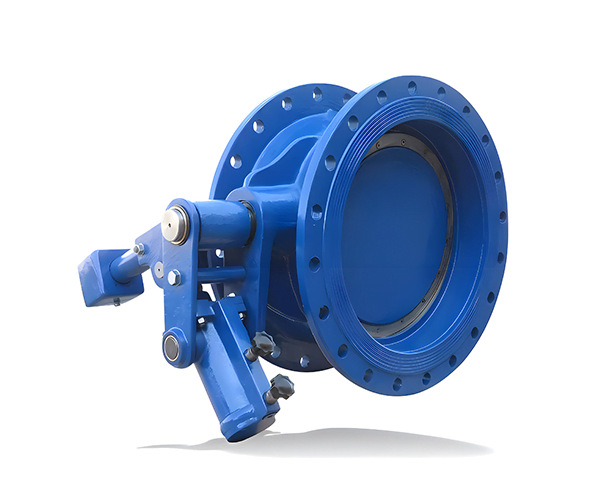

Product Overview | The Hydraulically Controlled Slow Closing Check Valve is a high-performance, intelligent valve designed for large-scale water supply, power generation, and industrial systems. Developed by our company based on decades of experience and advanced technologies, this valve integrates mechanical, hydraulic, and electrical systems to provide precise flow control, water hammer prevention, and energy efficiency. Available in two control system types—Standard Hydraulic Accumulator and Locking Hydraulic Accumulator—this valve is widely used in water treatment plants, power stations, steel mills, and chemical plants. It combines the functions of a check valve and a gate valve, offering reliable sealing, low flow resistance, and intelligent control. | |||||||||||||||

Applications | Water Supply Systems: Installed at pump discharge points in water treatment plants, municipal water networks, and irrigation systems. Power Generation: Used at turbine inlets in hydropower stations and at pump outlets in thermal power plant cooling systems. Industrial Pipelines: Suitable for non-corrosive gas and smoke pipelines, as well as process water systems.

| |||||||||||||||

Product Features | Intelligent Control System:Integrated hydraulic and electrical control systems enable local and remote operation.Compatible with Distributed Control Systems (DCS) for centralized management and联动 operation with pumps, turbines, and bypass valves.Manual operation is available for power outages or emergency situations. Adjustable Closure Speed:Hydraulic system allows precise adjustment of opening and closing times (5-120 seconds).Two-stage closing (fast and slow) effectively eliminates water hammer and protects pipelines and equipment. Advanced Sealing Design:Triple Eccentric Metal Seal: Suitable for high-temperature applications, with stainless steel and graphite layers for durable, leak-free performance. Double Eccentric Rubber Seal: Provides zero leakage and is easy to replace.Streamlined disc design reduces flow resistance (flow coefficient: 0.1-0.6). Space and Cost Savings:Combines the functions of a check valve and gate valve, reducing installation space and infrastructure costs. User-Friendly Interface:Multiple control options: Button-based, Text-based, or Touchscreen interfaces.Customizable interfaces available to meet specific customer needs. | |||||||||||||||

Structural Features | Valve Body: Horizontal design with long or semi-long stem configuration. Sealing Options:Triple Eccentric Metal Seal: Stainless steel and graphite layers for high-temperature applications.Double Eccentric Rubber Seal: Zero leakage with easy replacement. Hydraulic System:Includes oil pump, hydraulic block, solenoid valves, flow control valves, and accumulators.Two accumulators provide backup power for valve operation. Manual pump for emergency operation. Actuation Mechanism:Hydraulic cylinder and linkage system for smooth operation.Adjustable fast and slow closing speeds via flow control valves. | |||||||||||||||

Installation and Commissioning | Installation: Install at least 2 meters from the pump outlet to minimize turbulence.Ensure the valve is level and properly supported to avoid axial thrust on the pipeline. Commissioning:Verify manual operation and electrical connections.Adjust opening and closing speeds using flow control valves.Set pressure limits (KP1: 8 MPa, KP2: 14 MPa) and check for leaks.

| |||||||||||||||

Operation and Control | Local Control: Use the control panel to open, close, or stop the valve at any position.Adjust opening and closing speeds via hydraulic valves. Remote Control: Integrate with DCS for automated operation with pumps or turbines.Supports simultaneous or delayed valve and pump startup. Manual Operation: Use the manual pump to operate the valve during power outages or emergencies. | |||||||||||||||

Troubleshooting |

| |||||||||||||||

Product Parameters

| Size Range | DN300 to DN4000 (12" to 160") |

| Pressure Rating | PN0.25 to PN4.0 (0.25-4.0 MPa) |

| Test Pressure | Shell: 1.5×PNSeal: 1.1×PN |

| Operating Temperature | ≤80°C |

| Media | Freshwater, seawater, slurry, oil, and non-corrosive gases |

| Opening Time | DN<1000 mm: 15-60 secDN≥1000-4000 mm: 30-120 sec |

| Closing Time | Fast Close: DN<1000 mm: 5-30 secDN≥1000-4000 mm: 10-40 sec |

| Closing Time | Slow Close: DN<1000 mm: 10-60 secDN≥1000-4000 mm: 20-90 sec |

| Materials Body: | Carbon steel, cast iron, ductile iron |

| Materials Disc: | Carbon steel, cast iron, ductile iron |

| Materials Stem: | Stainless steel, carbon steel |

| Materials Seals: | Stainless steel/copper alloy (metal), NBR rubber (soft) |

Medium

Working conditions

Summarize

Hydraulically Controlled Slow Closing Check Valve Related Products

The following are similar products. You can search for other related products.