Double check valve backflow prevention

Double check valve backflow prevention

Double check valve backflow prevention

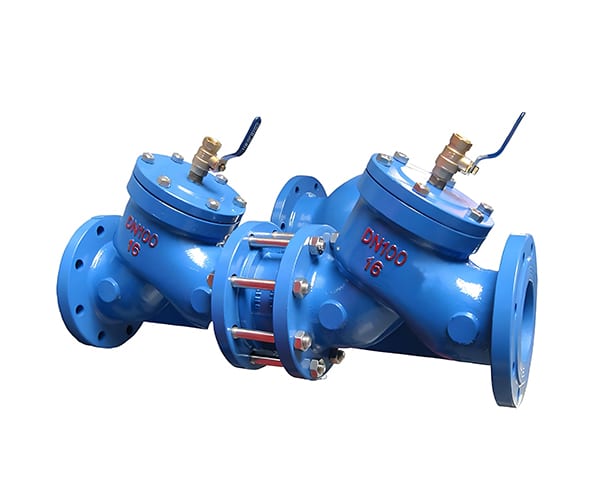

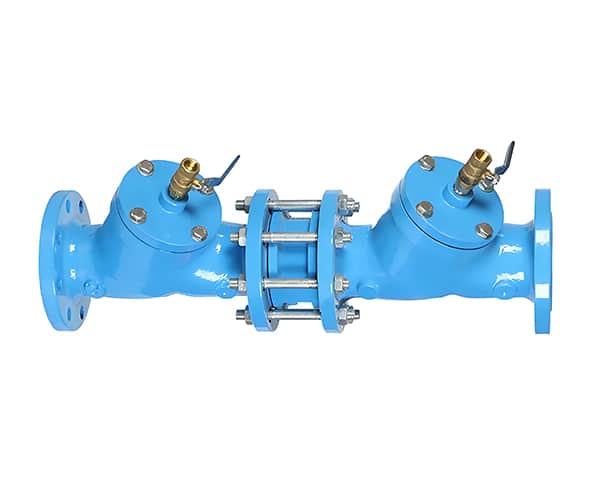

Product Overview | The Double Check Valve Backflow Preventer (DCVBP) is a critical safety device designed to protect potable water systems from contamination caused by reverse flow. Featuring two independent check valves and an optional intermediate pressure relief chamber, this valve ensures fail-safe operation in water supply, fire protection, and industrial applications. Constructed from bronze, stainless steel (304/316L), or ductile iron, the DCVBP complies with international standards (ASSE 1015, EN 1717) and is ideal for preventing backflow in systems where cross-connection risks exist. | |||||||||||||||

Key Features | Dual Check Valve Design:First Check Valve: Prevents reverse flow under normal pressure conditions.Second Check Valve: Acts as a backup barrier if the first valve fails.Pressure Relief Chamber (Optional): Automatically discharges intermediate pressure to prevent contamination. Low Resistance Flow:Optimized flow path minimizes pressure drop (Cv ≥ 1.2 for DN50).Ideal for high-flow systems requiring energy efficiency. Durable Materials:Bronze (C83600): Lightweight and corrosion-resistant for general use.Stainless Steel (304/316L): Superior resistance to chlorides and acids.Ductile Iron (EN-GJS-400-18): Heavy-duty construction for industrial applications. Compliance & Safety:Meets ASSE 1015, EN 1717, and ISO 5208 standards.Leakage Class VI (zero leakage under test conditions). Easy Maintenance:Modular design allows quick inspection and seal replacement.Test cocks for field testing without disassembly. | |||||||||||||||

Operational Advantages | Fail-Safe Protection: Dual check valves provide redundancy against backflow. Energy Efficiency: Low pressure drop reduces pump workload. Versatility: Suitable for water, air, and non-corrosive fluids. Compliance Ready: Pre-certified for global regulatory requirements. | |||||||||||||||

Comparison with Single Check Valves |

| |||||||||||||||

Product Parameters

| Size Range | DN50 to DN300 (2" to 12") |

| Pressure Rating | PN10 to PN25 (EN 1092) / Class 150 to 300 (ASME B16.34) |

| Temperature Range | -20°C to 120°C (EPDM seals) / -40°C to 80°C (FKM seals) |

| Body Materials | Bronze (C83600), 304/316L Stainless Steel, Ductile Iron (EN-GJS-400-18) |

| Seat Material | EPDM, NBR, or PTFE (FDA-compliant options available) |

| End Connections | Flanged (EN 1092/ASME B16.5) |

Medium

Working conditions

Summarize

Double check valve backflow prevention Related Products

The following are similar products. You can search for other related products.