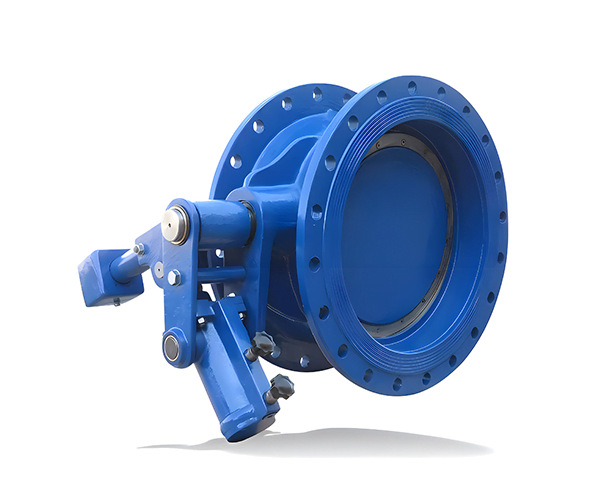

Large diameter check valve

Large diameter check valve

Large diameter check valve

Product Overview | The Large Diameter Check Valve is a high-performance, butterfly-style non-return valve designed for large-scale piping systems requiring reliable flow control and water hammer prevention. Suitable for water supply, wastewater treatment, power generation, and industrial processes, this valve prevents reverse flow and protects pipelines and equipment from damage caused by backflow or pressure surges. Available in sizes ranging from DN300 to DN2600 (12" to 104"), this valve is constructed from durable materials such as ductile iron, carbon steel, or stainless steel, ensuring long-term performance in demanding environments. Its butterfly disc design minimizes pressure drop and provides efficient, low-maintenance operation. | |||||||||||||||

Applications | Water Supply Networks: Installed at pump discharge points in municipal water systems and reservoirs. Wastewater Treatment: Used in effluent discharge and sludge handling systems. Power Generation: Protects cooling water circuits and condensate recovery systems in power plants. Industrial Pipelines: Suitable for large-scale process water, oil, and gas systems. | |||||||||||||||

Product Features | Butterfly Disc Design:Large-diameter disc ensures low resistance flow with a flow coefficient (Cv) of 0.1-0.6.Suitable for high-flow systems such as water supply and wastewater treatment plants. Durable Construction:Body materials: Ductile iron (EN-GJS-400-18), Carbon steel (ASTM A216 WCB), or Stainless steel (ASTM A351 CF8M).Internals: Stainless steel disc and spring for corrosion resistance and long service life. Reliable Sealing:Metal-to-Metal Seals: Suitable for high-temperature and high-pressure applications.Rubber Seals: Provides zero leakage in water and wastewater systems. Low Maintenance:Self-cleaning design and corrosion-resistant materials reduce downtime and maintenance costs. Compliance:Meets international standards such as AWWA C508, EN 1074, and ISO 5208. | |||||||||||||||

Operational Advantages | Water Hammer Prevention: Slow-closing mechanism reduces pressure surges and protects pipelines. Energy Efficiency: Low resistance flow minimizes pump energy consumption. Versatility: Suitable for horizontal or vertical installation (flow upwards). Ease of Installation: Flanged connections simplify integration into existing systems. | |||||||||||||||

Comparison with Standard Check Valves |

| |||||||||||||||

Product Parameters

| Size Range | DN300 to DN2600 (12" to 104") |

| Pressure Rating | PN10 to PN25 (EN 1092) or Class 150 to Class 300 (ASME B16.34) |

| Temperature Range | -10°C to 120°C (EPDM seals) / -20°C to 80°C (NBR seals) |

| Body Materials | Ductile Iron (EN-GJS-400-18), Carbon Steel (WCB), Stainless Steel (CF8M) |

| Disc Material | Ductile Iron (EN-GJS-400-18), Carbon Steel (WCB), Stainless Steel (CF8M) |

| Seat Material | EPDM, NBR, or PTFE for zero leakage |

| End Connections | Flanged (EN 1092, ASME B16.5) |

Medium

Working conditions

Summarize

Large diameter check valve Related Products

The following are similar products. You can search for other related products.