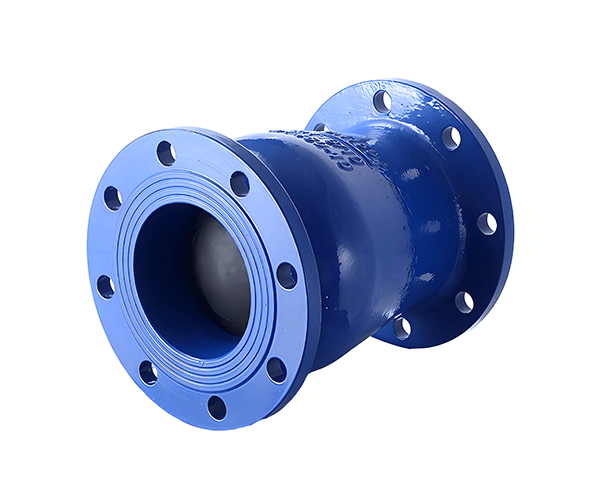

Silencing Check Valve

Silencing Check Valve

Silencing Check Valve

Product Overview | The Silencing Check Valve is a cost-effective non-return valve designed to prevent reverse flow and reduce water hammer in piping systems. Featuring a spring-assisted closure mechanism, this valve ensures quick sealing to minimize pressure surges, making it ideal for applications where noise reduction and budget considerations are important. Constructed from ductile iron, stainless steel, or bronze, this valve is durable and corrosion-resistant, suitable for water, steam, and oil systems. While it does not achieve zero water hammer, its spring-loaded design significantly mitigates pressure surges, offering a balance between performance and affordability.

| ||||||||||||||||||

Key Features | Spring-Assisted Closure:Spring mechanism ensures rapid disc closure, reducing water hammer and noise levels.Closure speed is fixed, providing consistent performance without adjustable settings. Cost-Effective Design:Simplified structure compared to hydraulic damping systems, offering a more affordable solution. Durable Construction:Body materials: Ductile iron (EN-GJS-400-18), Stainless steel (CF8M), or Bronze (C83600).Internals: Stainless steel disc and spring for corrosion resistance and long service life. Compact & Lightweight:Space-saving design simplifies installation in tight spaces. Compliance:Meets EN 1074, AWWA C508, and ISO 5208 standards for water and wastewater applications. | ||||||||||||||||||

Operational Advantages | Water Hammer Reduction: Spring-assisted closure minimizes pressure surges, though not completely eliminated. Cost-Effective: More affordable than hydraulic damping systems, offering excellent value for money. Low Maintenance: Self-cleaning design and corrosion-resistant materials. Ease of Installation: Compact and lightweight for quick integration into existing systems.

| ||||||||||||||||||

Comparison with Mute Check Valve |

| ||||||||||||||||||

Product Parameters

| Size Range | DN50 to DN600 (2" to 24") |

| Pressure Rating | PN10 to PN25 (EN 1092) or Class 150 to Class 300 (ASME B16.34) |

| Temperature Range | -10°C to 120°C (EPDM seals) / -20°C to 80°C (NBR seals) |

| Body Materials | Ductile Iron (EN-GJS-400-18), Stainless Steel (CF8M), Bronze (C83600) |

| Disc Material | Ductile Iron (EN-GJS-400-18), Stainless Steel (CF8M), |

| Seat Material | EPDM, NBR, or PTFE for zero leakage |

| End Connections | Flanged (EN 1092, ASME B16.5), Threaded (NPT/ISO 228) |

| Leakage Class | Class VI (ISO 5208) |

Medium

Working conditions

Summarize

Silencing Check Valve Related Products

The following are similar products. You can search for other related products.