wafer swing check valve

wafer swing check valve

wafer swing check valve

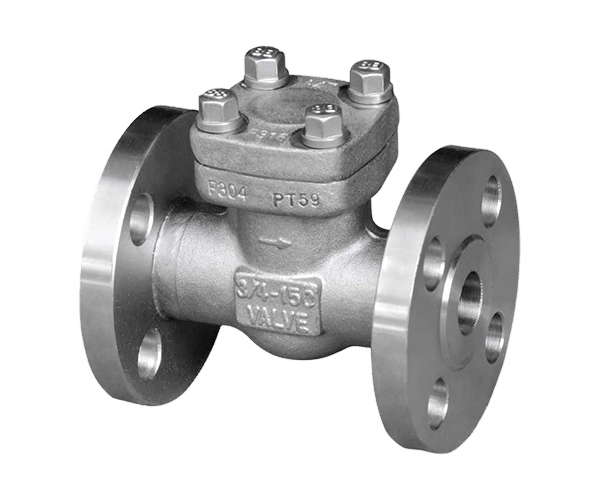

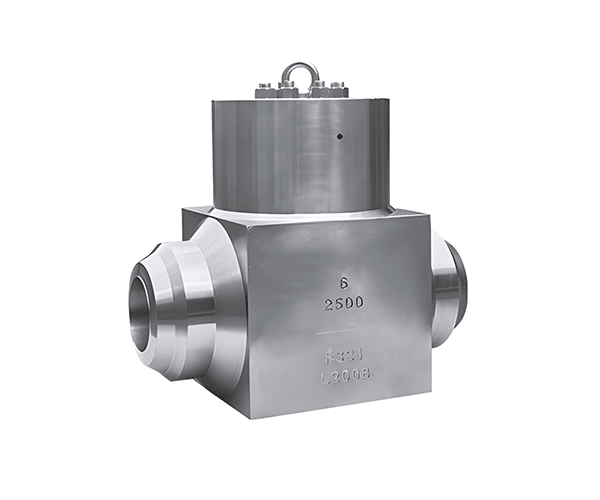

Product Overview | The Wafer Swing Check Valve is a compact, lightweight non-return valve designed to prevent reverse flow in piping systems where space and weight are critical considerations. Featuring a wafer-style design, this valve is installed between flanges, making it an ideal choice for applications requiring a low-profile solution without compromising performance. Constructed from carbon steel, stainless steel, or ductile iron, this valve is durable and corrosion-resistant, suitable for water, steam, oil, and gas systems. Its swing disc design ensures reliable sealing with minimal pressure drop, while its compact form factor simplifies installation and reduces overall system weight. |

Key Features | Wafer Design:Compact and lightweight, ideal for space-constrained installations.Installed between flanges, eliminating the need for additional bolts or gaskets. Swing Disc Design:Hinged disc allows smooth, low-resistance flow in the forward direction and immediate sealing upon flow reversal.Reduces water hammer effects compared to other check valve types. Durable Construction:Body materials: Carbon steel (ASTM A216 WCB), Stainless steel (ASTM A351 CF8M), or Ductile iron (EN-GJS-400-18).Internals: Stainless steel trim for corrosion resistance and extended service life. Low Maintenance:Self-cleaning disc design reduces wear and extends service life.Easy to inspect and repair without removing the valve from the pipeline. Compliance:Meets API 594, ASME B16.34, and ISO 17292 standards for general industrial applications.

|

Operational Advantages | Space-Saving Design: Compact wafer style reduces installation space and system weight. Reliable Sealing: Swing disc design ensures zero backflow, even at low pressures. Energy Efficiency: Minimal pressure drop reduces pump energy consumption. Ease of Installation: No additional bolts or gaskets required; fits between standard flanges.

|

Why Choose Our Wafer Swing Check Valve? | Proven Performance: Trusted in general-purpose industrial and commercial applications. Cost-Effective: Affordable solution with low installation and maintenance costs. Global Compliance: Meets API, ASME, and ISO standards for international projects. Versatility: Suitable for a wide range of media and installation orientations. |

Product Parameters

| Size Range | 2" to 24" (DN50 to DN600) |

| Pressure Rating | Class 150 to Class 600 (ASME B16.34) |

| Temperature Range | -29°C to 425°C (-20°F to 800°F) |

| Body Materials | Carbon Steel (WCB), Stainless Steel (CF8M), |

| Disc Material | Stainless Steel (410/316) |

| Seat Material | Metal-to-Metal or PTFE/Graphite for high-temperature applications |

| End Connections | Wafer (fits between flanges) |

Medium

Working conditions

Summarize

wafer swing check valve Related Products

The following are similar products. You can search for other related products.