ball check valve

ball check valve

ball check valve

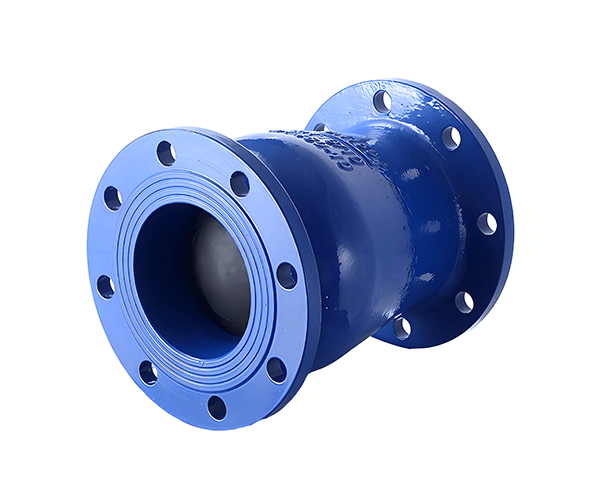

Product Overview | The Ball Check Valve is a highly efficient, non-return valve specifically designed for low-pressure systems (≤PN16/Class 150) to prevent reverse flow in water and sludge-containing media. Its robust construction and specialized features make it an ideal choice for applications where reliability, durability, and ease of maintenance are critical. The valve features a rubber-coated ball that ensures tight sealing even in abrasive or particulate-laden environments, such as wastewater treatment plants and industrial slurry systems. The flanged connection design (compliant with EN 1092-1 or ASME B16.5 standards) allows for easy installation and integration into existing pipelines, reducing downtime and labor costs. Engineered for low-pressure water systems, this valve is widely used in municipal water supply networks, stormwater drainage, and firefighting systems. Its ability to handle sludge and slurry media (up to 30% solids content) also makes it suitable for industrial applications, including mining, paper mills, and chemical processing plants. |

Working Principle | The valve operates through flow-driven actuation: 1.Forward Flow: Fluid pressure lifts the rubber-coated ball, allowing unobstructed flow with minimal pressure drop. 2.Reverse Flow Prevention: When flow stops or reverses, gravity and backpressure force the ball to seat against the valve body, creating an immediate seal. 3.Self-Cleaning Design: The ball’s movement during operation scrubs debris from the sealing surface, ideal for sludge or particulate-laden media. |

Key Features | 1.Low-Pressure Optimization: Rated for PN10/PN16 (EN 1092-1) or Class 150 (ASME B16.5), perfect for water and wastewater systems. 2.Rubber-Coated Ball:EPDM or NBR coating ensures tight sealing and corrosion resistance in abrasive/sludge environments. Compliant with WRAS/ACS standards for potable water safety. 3.Flanged Connection:EN 1092-1 (PN16) or ASME B16.5 (Class 150) flanges, pre-drilled for easy pipeline integration. 4.Debris Tolerance:Wide-body design prevents clogging in high-solid-content media (e.g., sewage, industrial slurry). |

Operational Advantages | Low Maintenance: No lubrication required; inspection via removable flange cover. Energy Efficiency: Low head loss (Kv value ≥ 0.8) reduces pump energy consumption. Sludge Resilience: Rubber coating resists abrasion from sand, grit, and fibrous materials. |

Why Choose Our Ball Check Valve? | Tailored for Water/Sludge: Specialized design avoids common failures in dirty media. Fast Delivery: Standard DN50-DN300 sizes in stock with 7-day global shipping. Certifications: ISO 9001 certified for regulatory compliance. Cost Savings: 5-year warranty on rubber components, reducing lifecycle costs. |

Product Parameters

| Nominal Diameter | DN50 to DN300 (2" to 12") |

| Nominal Pressure | PN10, PN16 (EN 1092-1) / Class 150 (ASME B16.5) |

| Temperature Range | -10°C to 80°C (EPDM) / -20°C to 60°C (NBR) |

| Body Material | Ductile Iron (EN-GJS-400-18), Epoxy-coated for corrosion protection |

| Ball Material | Stainless Steel Core + EPDM/NBR Rubber Coating (FDA/EC1935 compliant) |

| Seat Material | EPDM, NBR, or HNBR (optional) |

| Flow Direction | Horizontal or Vertical (Flow Upwards) |

Working conditions

Summarize

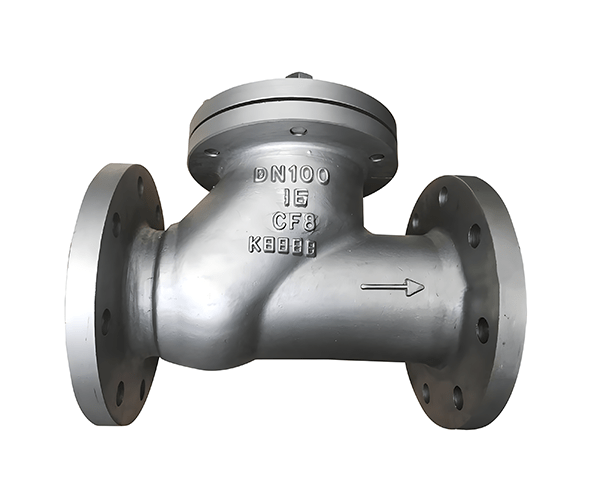

ball check valve Related Products

The following are similar products. You can search for other related products.