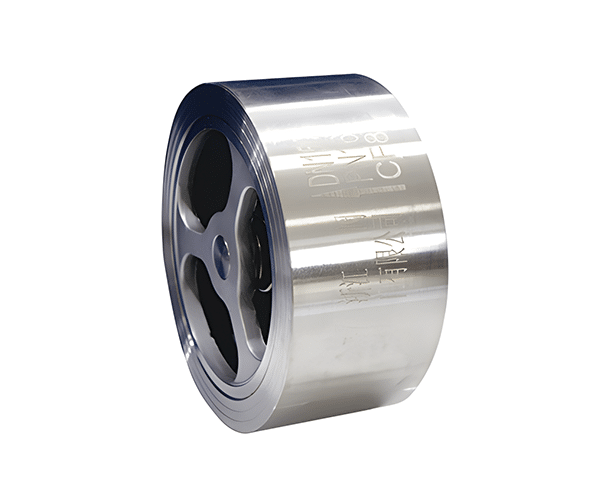

SS Wafer Check Valve Product Introduction

Product Overview:

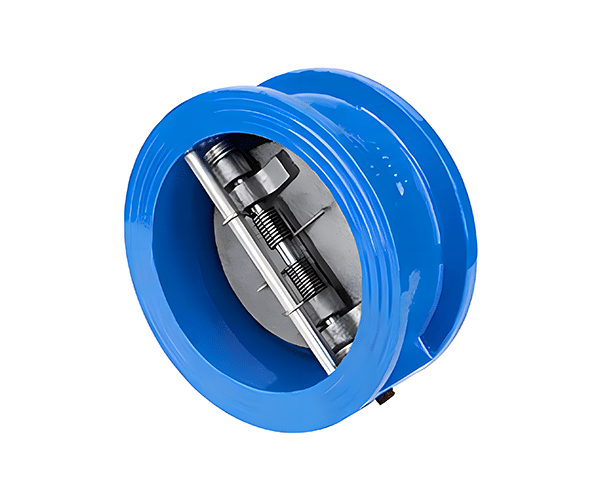

The SS Wafer Check Valve is designed for durability and corrosion resistance. It is made from high-quality stainless steel, such as 304 or 316. This valve features a compact wafer design, allowing it to fit between flanges. It is ideal for various industrial and commercial applications. The stainless steel construction ensures it can withstand harsh conditions.

Product Features:

- Stainless Steel Construction:

The valve is made from stainless steel. Options include 304 or 316 grades. Stainless steel resists corrosion, wear, and high temperatures. This ensures durability and a long service life.

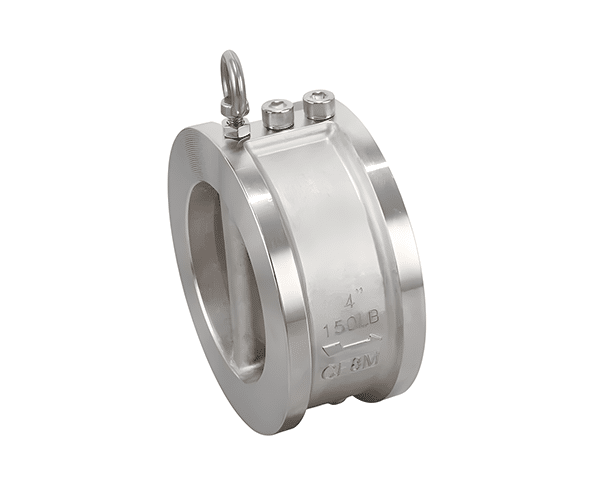

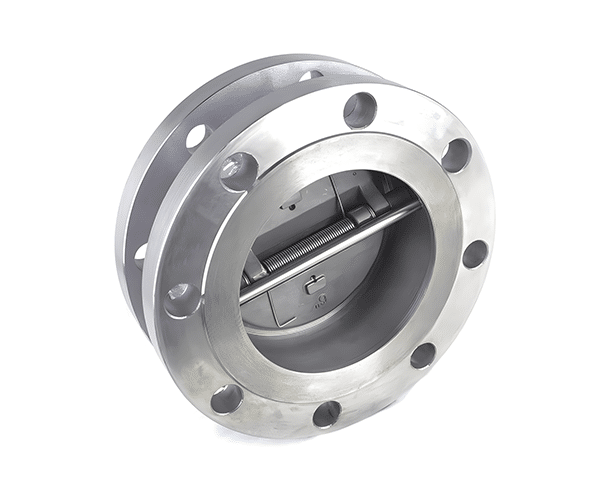

- Compact Wafer Design:

The wafer design allows the valve to be installed between flanges. This saves space and reduces the need for additional mounting hardware. It is suitable for tight spaces and simplifies installation.

- Effective Backflow Prevention:

The check valve prevents the backflow of media. It protects the system from reverse flow damage. The valve ensures one-way flow and maintains system integrity.

- Durable and Reliable:

The stainless steel construction and precision machining provide durability and reliability. The valve can withstand high pressure and temperature conditions.

- Low Pressure Drop:

The streamlined flow path minimizes pressure drop across the valve. This enhances system efficiency and reduces energy consumption.

- Sealed Design:

The valve features a precision-machined sealing surface. This design prevents leakage and reduces maintenance needs.

Applicable Media:

- Water:

Suitable for water treatment and distribution systems. The valve’s corrosion resistance ensures long-term performance.

- Chemicals:

Ideal for handling various chemicals, including acids and alkalis. The stainless steel construction resists chemical corrosion.

- Oil and Gas:

Used in oil and gas pipelines. The valve prevents backflow and protects the system from reverse flow damage. It handles high-pressure environments effectively.

- Food and Beverage:

Suitable for food and beverage processing applications. The valve’s corrosion resistance and easy maintenance make it ideal for hygienic environments.

Working Conditions:

- Pressure:

Designed to handle a wide range of pressures. Ensure that the valve meets the pressure requirements of the application.

- Temperature:

Capable of operating within a specified temperature range. Stainless steel provides stability and performance across varying temperatures.

- Flow Conditions:

Handles different flow rates effectively. The valve maintains reliable operation under varying flow conditions.

Place of Use:

– Water Treatment:

Applied in water treatment facilities to prevent backflow and maintain system integrity.

– Chemical Processing:

Used in chemical plants to handle corrosive media and prevent reverse flow.

– Oil and Gas Industry:

Ideal for pipelines in the oil and gas sector. It offers durability and protection against backflow.

– Food and Beverage Processing:

Suitable for applications in the food and beverage industry. It ensures hygiene and performance.

Summary:

The SS Wafer Check Valve provides a robust solution for backflow prevention. Its stainless steel construction ensures durability and corrosion resistance. The compact wafer design and effective backflow prevention make it ideal for various applications. These include water treatment, chemical processing, oil and gas pipelines, and food and beverage processing. The valve delivers consistent performance, efficiency, and long-term reliability.