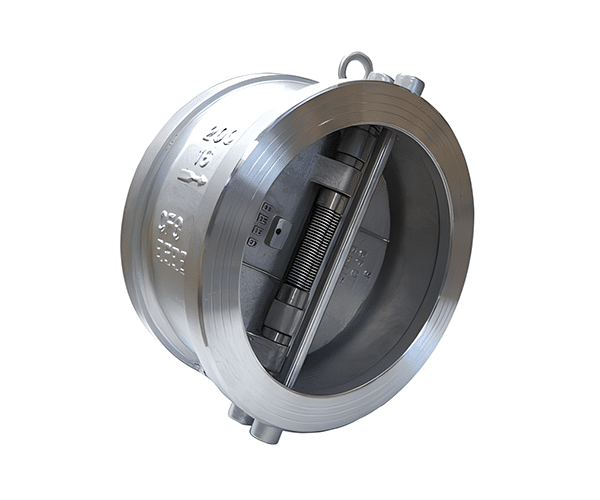

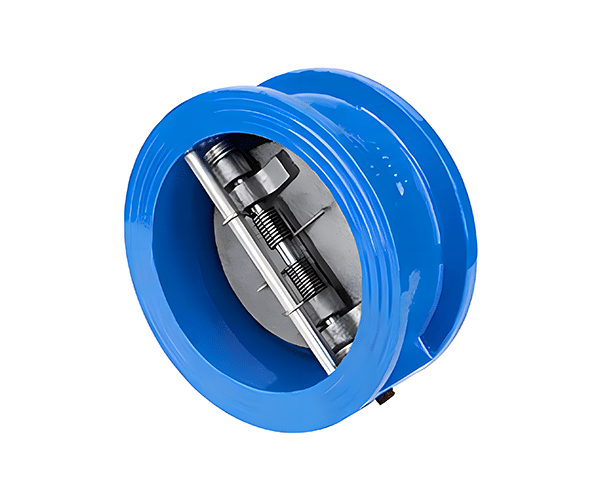

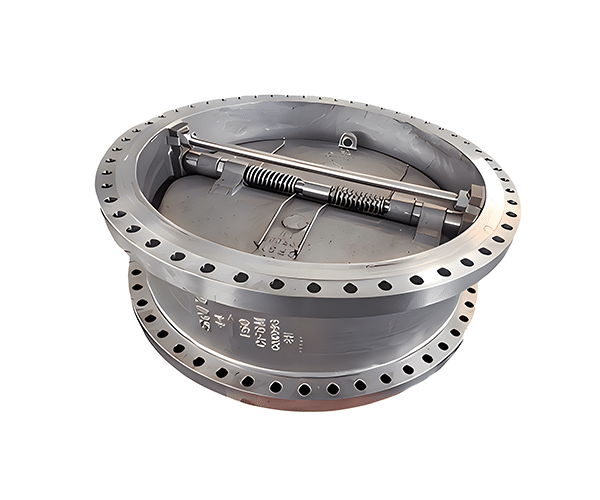

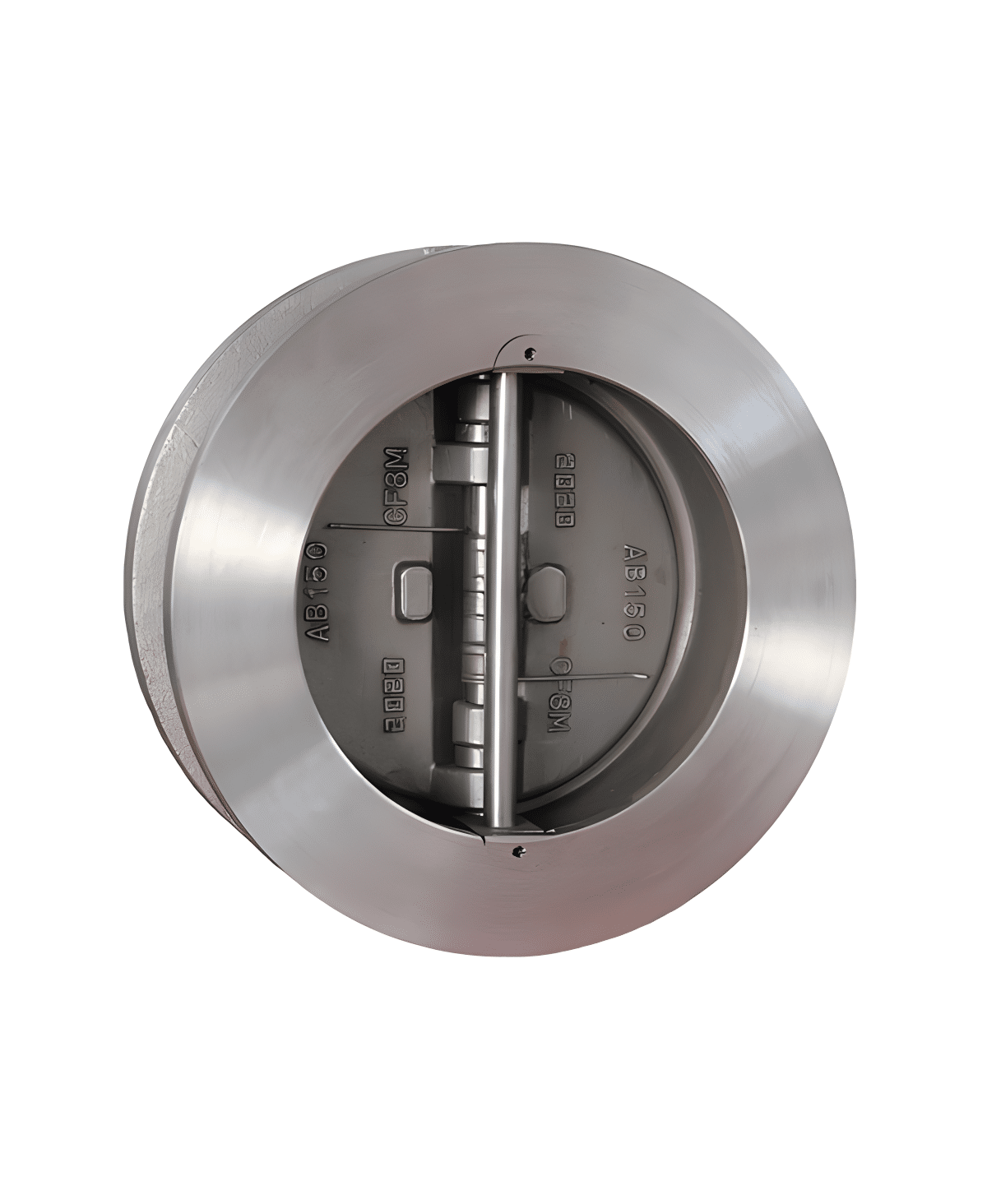

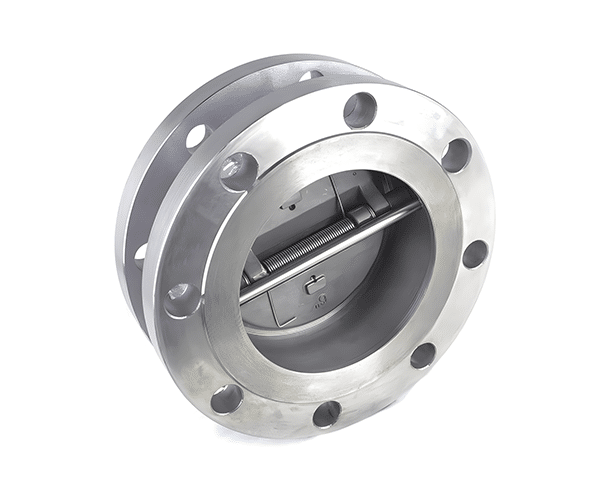

Product Name: Dual Plate Wafer Check Valve

Product Overview:

The Dual Plate Wafer Check Valve is designed to prevent backflow in pipeline systems. It features a dual plate mechanism with a spring return. This valve ensures reliable one-way flow control. The wafer design allows installation between flanges. It is ideal for applications with space constraints. This valve is used in various industries to protect systems and equipment from damage caused by reverse flow.

Features:

- Dual Plate Mechanism:

The valve is equipped with two plates that operate independently. This design ensures effective sealing and balanced operation. It minimizes the risk of backflow.

- Spring Return:

The dual plates are equipped with a spring return mechanism. This mechanism ensures the plates close securely and promptly. It enhances sealing reliability.

- Compact Wafer Design:

The slim wafer design facilitates easy installation between flanges. It is suitable for installations with limited space.

- Low Pressure Drop:

The dual plate and spring return mechanism reduce flow resistance. This results in a low-pressure drop across the valve. It improves overall system efficiency.

- Durable Construction:

The valve is made from high-quality materials such as cast iron, stainless steel, or alloy steel. It is built to withstand various operating conditions and provides long-lasting performance.

- Versatile Application:

The valve is suitable for a range of media, including water, oil, gases, and chemicals. It is adaptable to different industrial processes.

Advantages:

- Enhanced Sealing:

The dual plate design, combined with the spring return mechanism, provides superior sealing performance. It effectively prevents leakage and backflow.

- Space Efficiency:

The wafer design is compact and lightweight. It allows for installation in tight or congested areas.

- Cost-Effectiveness:

The valve typically offers a lower initial cost. It also reduces installation expenses compared to larger, more complex valves.

- Reliable Operation:

The combination of dual plates and spring return ensures balanced operation. It extends the valve’s service life.

Product Structure:

- Valve Body:

Constructed from durable materials such as cast iron, stainless steel, or alloy steel. The wafer body features a compact design that fits between flanges.

- Dual Plates:

The two plates open and close based on the flow direction. They are equipped with a spring return mechanism to ensure secure and prompt closing.

- Spring Return Mechanism:

The spring return mechanism ensures that the plates close promptly after each flow cycle. This improves sealing reliability.

- Sealing Surface:

The sealing surface is precision-machined to provide a tight seal. It minimizes leakage.

- Retaining Lug:

This component secures the valve between flanges. It ensures proper alignment during operation.

Design Standards:

– API 6D:

Standard for pipeline valves, ensuring design, materials, and performance meet industry requirements.

– ASME B16.34:

Provides guidelines for valve design and manufacturing, including construction and safety standards.

– API 598:

Covers valve inspection and testing to ensure reliability and performance.

– ISO 5208:

Specifies valve testing standards to ensure quality and functionality.

Suitable Media:

- Water:

Ideal for water distribution and treatment systems. This includes potable and wastewater pipelines.

- Oil:

Suitable for oil transport and processing systems.

- Gases:

Effective for handling various gases, including natural gas and compressed air, in industrial applications.

- Chemicals:

Suitable for use with non-corrosive chemicals in various industrial processes.

Operating Conditions:

- Pressure:

Designed to handle a range of pressures based on material and design specifications.

- Temperature:

Suitable for different temperatures depending on the material used and operational requirements.

- Flow Conditions:

Effective in managing both low and high flow rates. It ensures reliable performance.

Place of Use:

– Water Treatment Facilities:

Used in municipal and industrial water systems. It helps prevent backflow and protects equipment.

– Oil and Gas Industry:

Applied in pipelines and processing systems for handling oil and gas.

– Chemical Processing Plants:

Suitable for managing non-corrosive chemicals and ensuring safe operation.

– Power Generation:

Used in power plants for managing steam and cooling water systems.

Summary:

The Dual Plate Wafer Check Valve is an efficient solution for preventing backflow in pipeline systems. Its dual plate mechanism, enhanced by a spring return, ensures effective sealing and balanced operation. The compact wafer design offers space efficiency and cost-effectiveness. Constructed from durable materials, this valve is adaptable to various media and operating conditions. It is an ideal choice for maintaining system integrity across multiple industries.