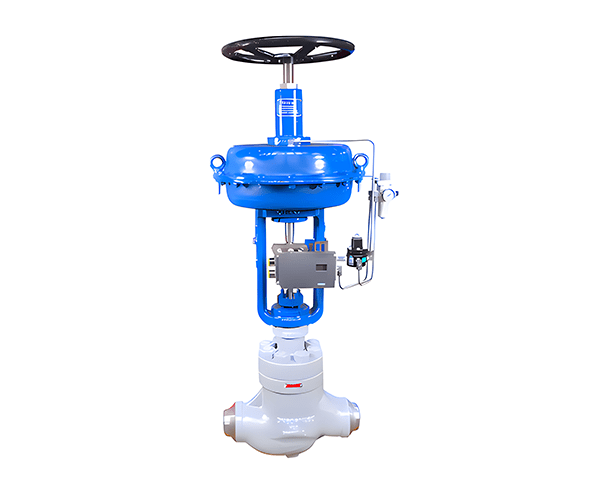

Single-Seat Pneumatic Control Valve Product Introduction

Product Overview:

The Single-Seat Pneumatic Control Valve is designed for precise flow regulation. It is suitable for a variety of industrial processes. The single-seat design is simple yet robust. This ensures reliable performance and tight shut-off. It also enhances control accuracy. The valve is ideal for applications that demand high precision and durability. It is a reliable choice for maintaining stable process conditions.

Key Features:

Pneumatic Actuator:

– Actuator Type: The valve has a diaphragm-type pneumatic actuator. This actuator is known for its smooth operation. It is also reliable across various pressure ranges.

– Operating Pressure: The actuator works effectively within a pressure range of 3 to 8 bar (43.5 to 116 psi). It is adaptable to a wide range of industrial applications.

– Control Signals: The valve is compatible with standard industrial control signals such as 4-20mA or 0-10V. This ensures precise and responsive control over valve positioning.

– Fast Response: The actuator provides quick and responsive valve movements. This optimizes process control and reduces reaction times.

Positioner for Enhanced Control:

– Positioner Integration: The valve is equipped with a high-performance positioner. This positioner ensures accurate and consistent valve positioning. It can handle various input signals, including 4-20mA. This allows for precise modulation of the control valve.

– Control Precision: The positioner improves control accuracy. It achieves a regulation precision of ±1% or better. This level of precision is crucial in processes where minor variations have significant impacts.

– Feedback Capability: The positioner provides real-time feedback on valve position. This is important for process monitoring and optimization. The feedback can be communicated to a central control system. This allows for integrated process management.

Valve Body Construction:

– Material Options: The valve body is available in various materials. These include cast steel, stainless steel (304, 316), and alloy steel. This allows customization based on the application’s media and operating conditions.

– Single-Seat Design: The single-seat configuration provides a tight shut-off. This minimizes leakage and is highly effective in applications requiring precise flow control.

– Seal Options: The valve comes with various sealing materials. These include PTFE, Viton, or metal seals, depending on process requirements. This ensures reliable performance under different operating conditions.

Performance Characteristics:

– Pressure Handling: The valve is suitable for low to medium pressure applications. It typically handles pressures up to 40 bar (580 psi). This ensures reliable control even in demanding environments.

– Temperature Range: The valve is designed to operate within a temperature range of -40°C to +200°C. This depends on the selected materials.

– Media Compatibility: The valve is versatile and compatible with a variety of media. This includes gases, liquids, and light slurries. It is suitable for diverse industrial applications.

Advanced Features:

– Manual Override: An optional manual override feature is available. This allows for manual operation during maintenance or if the pneumatic system fails.

– Fail-Safe Design: The valve is available in fail-open or fail-closed configurations. This enhances safety and reliability in critical applications.

– Actuator Speed: The speed of the actuator can be adjusted. This allows for fast or gradual valve response depending on the specific process requirements.

Applications:

The Single-Seat Pneumatic Control Valve is ideal for a wide range of industrial applications. This includes chemical processing, where it regulates the flow of various chemicals. It is also used in water treatment to control water flow in treatment plants. In HVAC systems, it regulates airflow and temperature. In the oil and gas industry, it controls the flow of gases and liquids, ensuring process stability.

Working Conditions:

– Pressure Range: The valve is designed for low to medium pressure applications, typically up to 40 bar (580 psi).

– Temperature Range: It operates effectively within a temperature range of -40°C to +200°C, depending on the material selection.

– Media Compatibility: The valve is compatible with various media, including gases, liquids, and light slurries. This makes it versatile for different industrial processes.

Advantages:

– High Precision Control: The integrated positioner provides precise regulation. It offers a control accuracy of ±1% or better. This ensures stable and efficient process management.

– Durable Construction: The valve is built with high-quality materials and advanced sealing technology. This ensures a long service life and consistent performance.

– Versatility: The valve is suitable for a wide range of applications. It offers flexible solutions tailored to meet specific process needs.

– Safety Features: The valve is available with fail-safe options and a manual override. This ensures reliable operation even in critical situations.

Conclusion:

The Single-Seat Pneumatic Control Valve is a reliable and precise solution. It is designed for controlling flow in various industrial applications. Its robust design, integrated positioner for enhanced control accuracy, and advanced features make it an ideal choice. It is suitable for industries requiring high precision, durability, and safety in their processes.