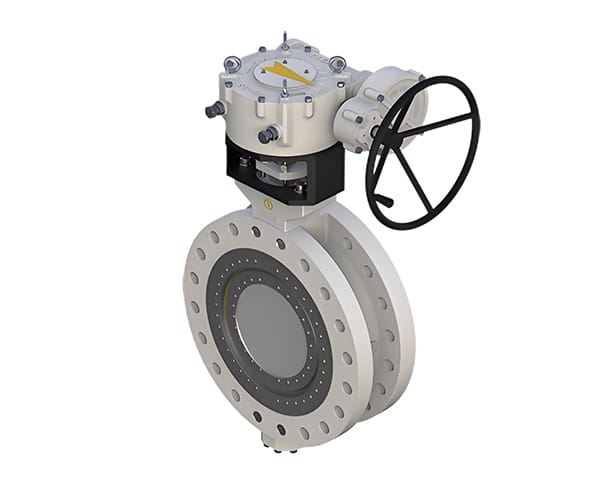

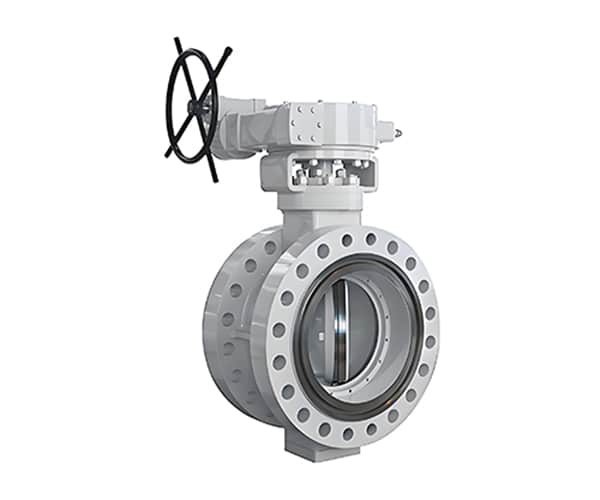

Metal Seat High Performance Butterfly Valve Product Introduction

Product Overview

The Metal Seat High Performance Butterfly Valve is designed for industrial applications that demand exceptional durability and performance. It offers superior resistance to high temperatures, high pressures, and abrasive media. The metal-to-metal sealing mechanism ensures long-lasting reliability and minimal leakage, even in extreme conditions. This makes it ideal for industries like petrochemical, power generation, and chemical processing, where valve performance is critical.

Difference Between High Performance and Standard Hard Sealing Butterfly Valves

- Sealing Efficiency:

– High Performance: Precision-engineered metal seat ensures a tighter seal. This reduces the risk of leakage in demanding environments.

– Standard Hard Sealing: While durable, it may not achieve the same level of sealing efficiency, especially under high pressure or extreme temperatures.

- Temperature and Pressure Resistance:

– High Performance: Operates at higher temperatures and pressures. This makes it suitable for more extreme applications.

– Standard Hard Sealing: Works well in moderate conditions. However, it may not perform as well in extreme circumstances.

- Durability:

– High Performance: Made from higher-grade materials. This offers greater resistance to wear and extends the valve’s service life in harsh environments.

– Standard Hard Sealing: Still durable but may require more frequent maintenance or replacement in tough conditions.

- Application Range:

– High Performance: Ideal for critical processes where failure could lead to significant downtime or safety risks.

– Standard Hard Sealing: Suitable for less critical applications where conditions are not as severe.

Metal Seal Characteristics

The metal seat in this high-performance valve is made from high-strength alloys like stainless steel. The metal-to-metal contact between the disc and the seat provides a robust seal. This ensures reliable performance, even in high-temperature or abrasive applications. The design reduces wear and enhances the valve’s ability to operate in high-pressure environments.

High Performance Features

- Durability: The metal seat is highly durable, withstanding harsh conditions and extending the valve’s service life.

- Tight Sealing: The precision-engineered metal seal minimizes leakage, even under high-pressure and high-temperature conditions.

- High Temperature and Pressure Resistance: The valve operates efficiently in environments where other materials might fail. It is suitable for steam systems, hot gases, and high-pressure fluids.

- Efficient Flow Control: The design allows for precise flow regulation, which is essential in processes that require accurate control over fluid dynamics.

Suitable Media and Working Conditions

- Suitable Media:

– Abrasive Fluids: Ideal for handling slurries, powders, and other abrasive media. The metal seat prevents wear and ensures a durable seal.

– Corrosive Media: Performs well in environments with acidic or corrosive fluids, especially when made from corrosion-resistant alloys.

– High-Temperature Fluids: Excels in applications with steam, hot gases, and high-temperature oils. The valve maintains a reliable seal despite intense heat.

- Working Conditions:

– High Pressure: Designed to function effectively in high-pressure systems, ensuring safety and efficiency.

– High Temperature: Suitable for high-temperature environments like power generation and petrochemical processing.

– Harsh Environments: The robust construction and metal sealing mechanism make this valve ideal for harsh industrial settings, including those with abrasive or corrosive media.

Summary

The Metal Seat High Performance Butterfly Valve is known for its durability and sealing efficiency, especially in extreme conditions. Compared to standard hard sealing butterfly valves, it offers better resistance to temperature, pressure, and wear. Its design ensures reliable operation in critical industrial processes. This makes it a valuable investment for maintaining safety and efficiency in demanding environments.