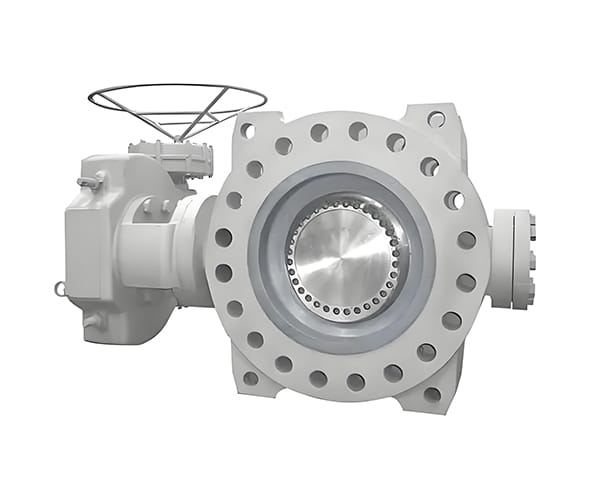

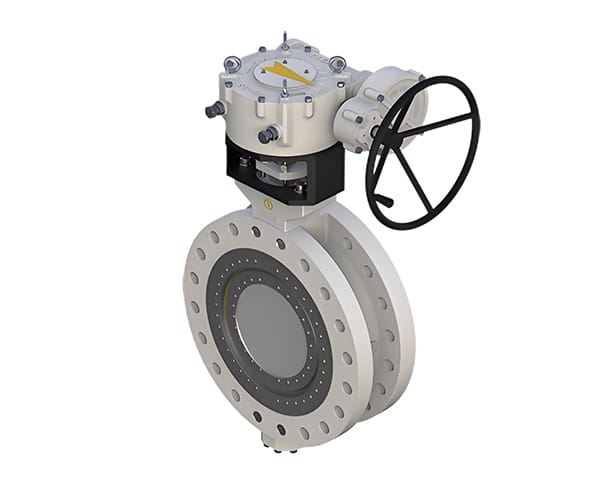

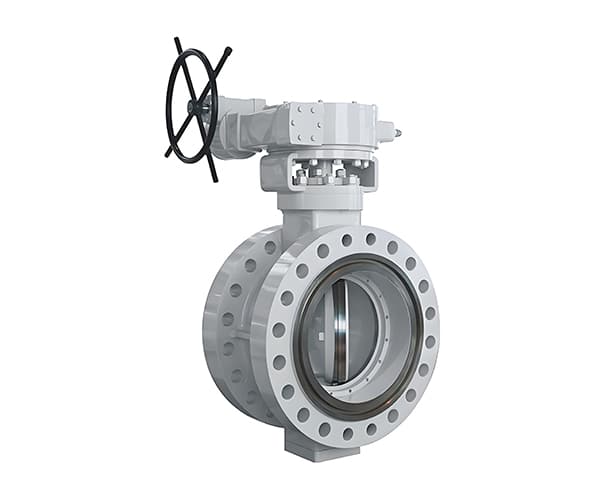

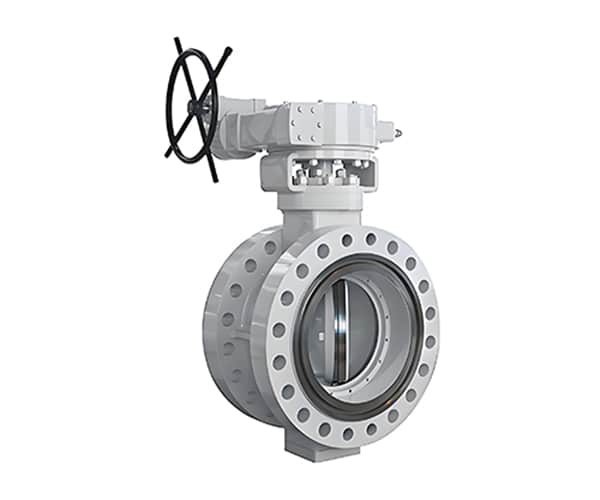

Hard Sealing Butterfly Valve Product Introduction

Product Overview

The Hard Sealing Butterfly Valve is designed for industrial applications that demand high reliability and durability. Unlike soft-seal valves, this valve uses a metal-to-metal sealing mechanism. It is resistant to high temperatures, high pressures, and abrasive media. This makes it a preferred choice in industries such as petrochemical, power generation, and chemical processing. The valve’s components, typically made from stainless steel or other robust alloys, ensure a secure and long-lasting seal. The Hard Sealing Butterfly Valve is crucial for systems where valve performance is critical to safety and efficiency.

Hard Seal Structure

The valve features a metal-to-metal sealing structure. Both the disc and seat are made from hardened materials like stainless steel. This design ensures a tight and reliable seal, even in extreme conditions. The metal seat resists wear, making the valve suitable for abrasive and corrosive media. The hard seal structure enhances the valve’s lifespan and reduces maintenance needs.

Advantages of Hard Sealing Butterfly Valve

- Durability: The hard seal design increases the valve’s durability. It withstands wear from abrasive and corrosive media, extending its operational life.

- High-Temperature Resistance: The metal-to-metal seal resists high temperatures, making it suitable for steam, hot gases, and high-temperature fluids.

- Pressure Resistance: The valve’s robust construction allows it to operate effectively in high-pressure environments, ensuring a reliable seal.

- Tight Sealing: The precision-engineered metal seat minimizes leakage, maintaining efficiency and safety.

Disadvantages of Hard Sealing Butterfly Valve

- Higher Torque Requirement: Operating the valve may require more torque, especially in larger sizes, leading to higher energy consumption.

- Cost: The high-quality materials and precision engineering make these valves more expensive than soft-seal valves.

- Less Flexibility: Hard sealing valves require precise installation and maintenance due to their less forgiving nature.

Suitable Media and Working Conditions

- Suitable Media

– Abrasive Fluids: Ideal for handling slurries, powders, and chemicals. The metal seat prevents wear and ensures a tight seal.

– Corrosive Media: Suitable for corrosive chemicals if the valve materials are chosen correctly. Stainless steel and special alloys provide excellent corrosion resistance.

– High-Temperature Gases and Fluids: The valve handles steam, hot gases, and high-temperature oils effectively due to its heat resistance.

- Working Conditions

– High Pressure: The valve performs well in high-pressure environments, ensuring sealing integrity and system safety.

– High Temperature: Effective in high-temperature applications, making it ideal for power generation and petrochemical processing.

– Harsh Environments: The valve is durable in harsh environments, suitable for industries like mining, oil and gas, and chemical processing.

Summary

The Hard Sealing Butterfly Valve is robust and reliable, designed for demanding industrial environments. Its metal-to-metal seal offers durability and resistance to extreme conditions. Although it requires more torque and is more expensive, its long-term benefits make it a valuable investment for critical applications.