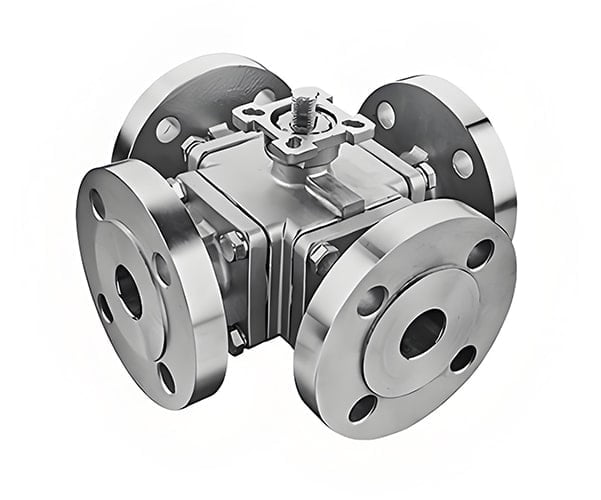

Product Overview

The four-way ball valve is a multi-channel control valve. It plays an important role in fluid flow switching and distribution in industrial pipeline systems. With its unique design and excellent performance, it provides efficient and reliable solutions for various complex processes.

Structural Form

- “T” Shaped Structure

– The flow channels are distributed in a “T” shape. There are usually three channels on the sphere.

– One of the channels is perpendicular to the other two channels. This allows the medium to switch flow direction: one in and two out, or two in and one out. It can achieve various complex splitting and converging combinations.

– For example, the medium can enter from one inlet and flow out from two outlets in equal amounts or in a certain proportion. Alternatively, two media can enter from two inlets, mix in the valve, and flow out from one outlet. - “L” Shaped Structure

– The flow channel is “L” shaped. There are generally two channels on the sphere with an angle of 90 degrees.

– It is mainly used to switch between two flow directions. For instance, the medium enters from one inlet and flows out from the other outlet. - “X” Shaped Structure

– The flow channels cross in an “X” shape, and there are four channels on the sphere.

– This structure enables more diversified and flexible flow direction switching to adapt to complex process requirements.

4-way ball valve Operating Conditions

- Chemical Industry

– In chemical production, it is used for mixing, separation, and transportation of different chemical substances.

– For example, in fine chemical synthesis, it precisely controls the flow direction and flow rate of multiple reaction raw materials for efficient chemical reactions. - Oil and Gas Field

– The valve is used for distributing and switching multi-phase fluids in oil and gas gathering and transportation systems.

– It ensures the stability and safety of oil and gas during extraction, processing, and transportation. - Energy Industry

– In the cooling circulating water system of thermal power plants, it switches water flow between different pipelines. This improves energy utilization efficiency. - Pharmaceutical Industry

– The valve meets strict hygiene standards and purity requirements. It ensures accurate flow control of media during pharmaceutical production. - HVAC Systems

– It adjusts the distribution of hot and cold water between pipes in different areas. This allows precise regulation of indoor temperature and humidity.

Product Features and Advantages

- Excellent Sealing Performance

– The valve uses advanced sealing technology and high-quality sealing materials. This ensures effective prevention of media leakage under various pressure and temperature conditions. - Flexible and Convenient Operation

– Simply rotate the sphere 90 degrees or 180 degrees to quickly switch the flow direction. This makes operation simple and labor-saving. - Strong Corrosion Resistance

– The valve body and ball are usually made of stainless steel or other corrosion-resistant materials. It can operate stably for a long time in corrosive media environments. - High Stress Tolerance

– The valve is carefully designed and manufactured. It can withstand high working pressure and adapt to high-pressure working conditions. - Low Maintenance Cost

– The structure is relatively simple and easy to maintain. This reduces equipment downtime and repair costs.

In summary, the four-way ball valve has become an indispensable part of industrial pipeline systems. Its diverse structural forms and wide range of applications provide a strong guarantee for achieving efficient, safe, and precise fluid control.