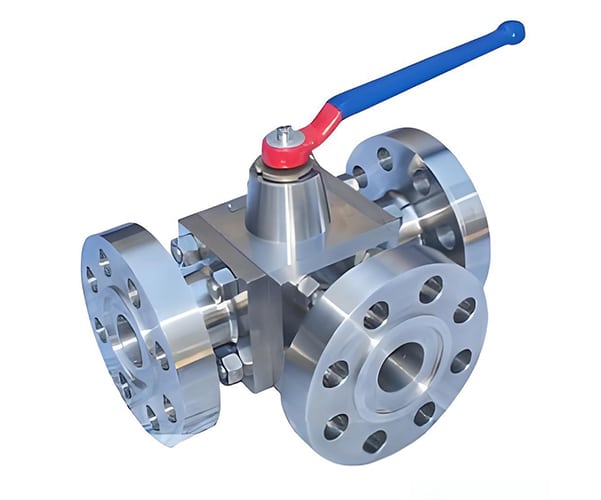

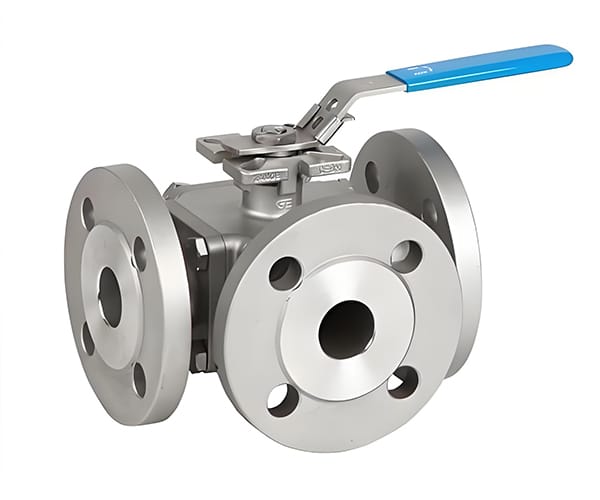

High pressure 3 way ball valve Product Overview

The high-pressure three-way ball valve is a premium valve designed for precise fluid control under extreme pressure. Its maximum working pressure can reach 600LB, demonstrating excellent pressure resistance. This valve operates stably in high-pressure environments, ensuring efficient and safe fluid transmission.

The valve is made from high-quality forged steel. The fine forging process ensures that the metal fiber structure is aligned with the product’s outline, significantly enhancing its strength and toughness. This valve handles high-temperature and high-pressure steam, corrosive chemical media, and pressure shocks from frequent switching operations. With its sturdy structure and excellent materials, it provides reliable fluid control solutions for various industrial processes.

In terms of design, the high-pressure three-way ball valve considers fluid characteristics and operational requirements for different conditions. Its unique three-way structure allows flexible switching between three flow channels, meeting complex fluid distribution and flow direction control needs. It can guide fluid from one channel to two or merge fluid from two channels into one with a simple rotation. This precise control of fluid direction and distribution optimizes the efficiency of industrial systems.

Additionally, the valve features advanced sealing technology and high-precision manufacturing. It ensures zero leakage at pressures up to 600LB, preventing safety risks, environmental pollution, and resource waste from leaks. Its compact design saves installation space and facilitates installation and maintenance in tight spaces, reducing costs and maintenance difficulty.

Description and Difference Between L-Type and T-Type Structures

L-Type Structure

The flow channel of the L-type high-pressure three-way ball valve is “L” shaped. It is used to switch between two media, closing one while allowing the other to flow. For example, in an industrial refrigeration system, it switches between refrigerants A and B. In one position, refrigerant A flows while refrigerant B is cut off; in another position, refrigerant B flows while refrigerant A is cut off.

T-Type Structure

The flow channel of the T-type high-pressure three-way ball valve is “T” shaped. It connects and cuts off any two of the three media, allowing for confluence or diversion. For instance, in a chemical process, raw materials A, B, and C may need confluence or diversion. When the ball valve is in a specific position, raw materials A and B can flow together out of one outlet, or raw material A can be diverted to two different outlets.

Differences Between L-Type and T-Type

1. Different Flow Control Functions

– L-type: Used for switching between two media.

– T-type: Used for confluence or diversion of three media.

2. Differences in Application Scenarios

– L-type: Suitable for simple media switching scenarios, like dual energy supply systems.

– T-type: Suitable for complex control of three-way media, such as multi-component mixing in fine chemicals.

Advantages of Forged Steel Materials

1. High Strength and Durability

– Forged steel has a dense internal structure, significantly improving strength. It withstands pressures up to 600LB, ensuring stable operation under extreme conditions. For example, in large petrochemical plants, it maintains performance in high-pressure environments.

2. Excellent Toughness and Impact Resistance

– Forged steel’s good toughness allows it to withstand fluid shock and pressure fluctuations, reducing valve damage risk. In systems with frequent pressure changes, like hydraulics, it ensures normal valve operation.

3. Excellent Machining Performance

– Forged steel allows for the manufacture of high-precision, complex-shaped components, ensuring a close fit between parts and improving sealing performance and reliability.

Product Features

1.Precision Sealing Design

– Uses advanced sealing technology to ensure zero leakage under high pressure, preventing safety hazards and resource waste from leaks.

2. Flexible Operating Performance

– The valve stem is designed for easy, labor-saving operation, allowing quick and accurate flow channel switching to improve efficiency.

3. Corrosion Resistance

– Special surface treatment or corrosion-resistant forged steel materials enhance resistance to corrosive media, extending valve life.

Technical Parameters

1. Nominal Diameter: 2 inches – 24 inches

2. Working Pressure: 150LB – 600LB

3. Applicable Temperature: ≤ 350℃

4. Connection Method: Flange connection

Installation and Maintenance

1. Before installation, check the cleanliness of the valve and pipeline to avoid impurities affecting sealing performance.

2. Install in the correct direction and position, using appropriate tools and tightening force.

3. Perform regular maintenance, checking seals, valve stems, valve bodies, and other components. Replace worn or damaged parts promptly.

Application Areas

1. Petrochemical Industry

– Used for fluid distribution and control in high-pressure pipeline systems.

2. Energy Field

– Used in high-pressure steam systems in thermal power plants.

3. Pharmaceutical Industry

– Meets strict hygiene and process requirements and controls the flow direction of the medium.

High-pressure forged steel three-way ball valves provide safe and efficient solutions for fluid control under high-pressure conditions, thanks to their excellent performance and reliable quality.