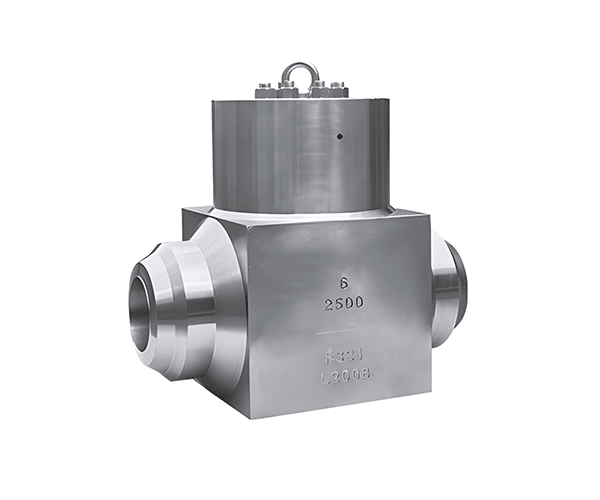

Forged Steel Swing Check Valve

Product Overview

The Forged Steel Swing Check Valve is specifically designed for applications requiring high pressure and small bore pipelines. This valve is commonly used in industries where the control of fluid flow is critical, such as in oil and gas, power generation, and petrochemical processing. The valve’s robust construction and reliable performance make it an ideal choice for demanding environments where durability and safety are paramount.

Key Features

High-Pressure Capability: The Forged Steel Swing Check Valve is built to handle high-pressure conditions, making it suitable for applications where pressure exceeds the limits of cast steel or other materials. It is particularly effective in ensuring the unidirectional flow of media in high-pressure pipelines.

Compact Design for Small Bore Applications: This valve is typically used in small bore pipelines, where space is limited, and precision is required. The compact design ensures that the valve fits seamlessly into tight spaces without compromising on performance.

Forged Steel Construction: Made from high-quality forged steel, this valve offers superior strength and durability compared to valves made from cast materials. The forging process enhances the material’s mechanical properties, providing excellent resistance to wear, fatigue, and pressure.

Reliable Backflow Prevention: The swing check valve mechanism operates automatically to prevent backflow. When the flow reverses, the valve disc swings into the closed position, ensuring that the medium only flows in the intended direction.

Corrosion Resistance: The valve’s forged steel body is often treated or coated to resist corrosion, making it suitable for use in harsh environments, including those involving corrosive media or extreme temperatures.

Product Structure

Valve Body: The body of the Forged Steel Swing Check Valve is made from forged steel, which provides superior strength and durability. The forged steel construction ensures that the valve can withstand high pressure and is less susceptible to defects like porosity or inclusions, which can occur in cast steel.

Valve Disc: The valve disc is designed to swing freely within the valve body. When the flow is in the correct direction, the disc opens to allow passage of the medium. Upon flow reversal, the disc swings back to seal against the valve seat, preventing backflow. The disc is typically made from the same forged steel as the valve body or a more wear-resistant material, depending on the specific application.

Valve Seat: The valve seat is a critical sealing surface. It is precision-machined and often hard-faced with materials like Stellite (STL) to provide a durable and tight seal. This ensures long-term reliability even under high-pressure conditions.

Hinge Pin and Arm: The hinge pin and arm, which connect the valve disc to the body, are designed for durability and smooth operation. These components ensure that the disc moves freely and returns to the closed position when necessary.

Flange or Butt Weld Ends: Depending on the application, the valve may feature flanged or butt-welded ends for secure and leak-proof connections. Flanged ends are suitable for applications requiring easy disassembly and maintenance, while butt-welded ends offer a more permanent connection for high-pressure pipelines.

Design Standards

Design Specifications: The Forged Steel Swing Check Valve is designed according to international standards such as API 602, ASME B16.34, and BS 1868. These standards ensure that the valve meets the required safety, performance, and dimensional criteria for high-pressure applications.

Manufacturing Standards: The valve is manufactured in compliance with stringent standards like ASME, ASTM, and ISO. This ensures consistent quality and reliability. The manufacturing process includes rigorous material selection, precision forging, machining, and thorough quality control.

Inspection and Testing: Each valve undergoes rigorous testing procedures, including hydrostatic testing and leakage testing, to verify its performance under specified pressure conditions. These tests ensure that the valve meets the necessary pressure ratings and functions reliably in high-pressure environments.

Applicable Media and Locations

Applicable Media: The Forged Steel Swing Check Valve is suitable for a wide range of media, including high-pressure steam, oil, gas, and other non-corrosive or mildly corrosive fluids. The forged steel construction ensures compatibility with these media, providing long-term reliability and performance.

Applications: This valve is ideal for high-pressure applications in industries such as oil and gas, power generation, and petrochemical processing. It is commonly used in small bore pipelines where precise flow control is required, and space is limited. The valve is particularly effective in preventing backflow in high-pressure systems, ensuring the integrity and safety of the entire pipeline.

Summary

The Forged Steel Swing Check Valve is a robust and reliable solution for high-pressure, small bore applications. With its durable forged steel construction and compact design, it provides excellent performance in demanding environments. Adhering to international design and manufacturing standards, this valve is a dependable choice for industries where safety and reliability are critical. Whether in oil and gas, power generation, or petrochemical processing, the Forged Steel Swing Check Valve ensures secure, unidirectional flow and prevents backflow, even under the most challenging conditions.